When choosing between water-based and oil-based polyurethane, consider their composition, drying times, and finish quality. Water-based options dry faster, emit fewer fumes, and offer a clearer look, while oil-based provides a warmer hue, stronger durability, and richer sheen. Water-based finishes are easier to clean and environmentally friendly, but oil-based is better for high-traffic areas. Understanding these differences helps you make the best choice for your project—if you want more details, keep exploring the specifics.

Key Takeaways

- Water-based polyurethane dries faster, emits fewer fumes, and has lower VOC levels, making it more eco-friendly and suitable for indoor use.

- Oil-based polyurethane offers a richer, amber hue, greater durability, and superior wear resistance, ideal for high-traffic surfaces.

- Water-based finishes provide a clear, glossy appearance with minimal color change, while oil-based finishes add warmth and a softer sheen.

- Water-based products are generally less expensive, easier to clean up with water, and more readily available at hardware stores.

- Oil-based polyurethane releases stronger fumes, requires longer drying times, and poses higher health and environmental risks during application.

Composition and Chemical Makeup

Water-based polyurethane consists mainly of acrylic or polycarbonate resins dispersed in water, making it a more environmentally friendly option. Its chemical composition includes these resins combined with a small amount of coalescing agents, pigments, and stabilizers. Unlike oil-based formulas, it has a low solvent content, which reduces emissions and health risks. The solvent content in water-based polyurethane is primarily water, with minimal volatile organic compounds (VOCs), making it safer and easier to clean up. This lower solvent level also influences the drying time and finish quality. Overall, the chemical makeup ensures a durable, flexible coating that’s less harmful to your environment and health, while still providing excellent protection for your surfaces. Additionally, seasonal variations can influence the drying and curing process, requiring adjustments in application techniques.

Application Process and Ease of Use

When applying polyurethane, you’ll notice differences in techniques and tools needed for water-based and oil-based formulas. Drying and curing times also vary, affecting your project schedule. Plus, cleanup is easier with water-based options, but both require careful handling for best results. For automotive projects, such as Mazda tuning enhancements, choosing the right polyurethane can impact the durability and appearance of interior and exterior components, especially when considering environmental factors and long-term wear polyurethane properties.

Application Techniques and Tools

Applying polyurethane effectively depends on your choice of tools and techniques, which can considerably impact the final finish. For brush techniques, use high-quality, natural bristle brushes to achieve smooth, even coats. Apply thin layers, following the grain of the wood, and avoid over-brushing to prevent bubbles and streaks. Spray application offers a faster, more uniform coverage, especially for larger surfaces, but requires proper equipment and ventilation. Keep the spray at a consistent distance and move evenly to prevent drips and uneven layers. Both methods demand patience and attention to detail to ensure a professional-looking result. Whether you choose brushing or spraying, proper technique is essential for a durable, beautiful finish. Additionally, application process can be optimized by understanding the differences between water‑based and oil‑based polyurethane to select the best approach for your project.

Drying and Curing Time

Drying and curing times vary considerably between water-based and oil-based polyurethane, affecting how quickly you can use your finished project. Typically, water-based polyurethane dries faster, allowing you to apply multiple coats in one day. In contrast, oil-based polyurethane takes longer to dry, requiring patience for ideal results. Consider these key points:

- Water-based polyurethane dries in about 2-4 hours, speeding up application techniques.

- Oil-based polyurethane may need 8-24 hours between coats.

- Faster drying impacts the finish appearance, reducing the risk of dust settling on wet surfaces.

- Longer curing times for oil-based formulas can improve durability and smoothness.

- The drying process is influenced by environmental factors such as temperature and humidity, which can alter expected drying times.

Choosing the right type depends on your project timeline and desired finish, influencing both ease of use and the final look.

Ease of Cleanup

Because of their different solvent compositions, water-based and oil-based polyurethanes vary considerably in cleanup ease. Water-based polyurethane dissolves easily in water, making solvent cleanup straightforward and quick. You can simply rinse brushes, rollers, and tools with water, reducing the need for harsh chemicals. In contrast, oil-based polyurethane requires solvent cleanup with mineral spirits or paint thinner, which involves handling stronger chemicals and more careful disposal. The chemical reactions involved in cleaning oil-based finishes are more complex, often leaving residues if not thoroughly cleaned. This necessity for careful disposal can also impact safe handling practices, making cleanup more time-consuming and potentially messier. Overall, water-based polyurethane offers a more convenient and less hazardous cleanup process, saving you time and effort after application.

Drying and Curing Times

You’ll notice that water-based polyurethane dries faster than oil-based varieties, often within a few hours. However, the curing process for both can take days or even weeks to reach maximum durability. Understanding these timing differences helps you plan your project and achieve the best finish. Additionally, proper ventilation during drying reduces indoor air pollution associated with volatile organic compounds emitted by solvents.

Drying Speed Differences

While both water-based and oil-based polyurethanes serve to protect and enhance wood surfaces, they differ markedly in how quickly they dry and cure. Water-based polyurethanes typically dry faster, often within 2-4 hours, allowing for quicker application techniques. In contrast, oil-based versions may take 8-24 hours to dry between coats. The drying environment considerably impacts these times: high humidity slows drying, especially for water-based formulas, while lower temperatures delay oil-based drying. To optimize results, you should consider these factors: 1. Humidity levels 2. Temperature 3. Application techniques 4. Ventilation conditions. Additionally, understanding the drying and curing times of each type can help prevent issues like tackiness or incomplete curing, ensuring a durable finish.

Curing Duration Variations

Drying speed is just one part of the story; curing duration determines when the polyurethane fully hardens and reaches maximum durability. Water-based polyurethanes typically cure faster, allowing you to apply additional coats sooner, but they may need extended curing times for ideal hardness. Oil-based options often take longer to cure, but they develop a durable finish over time. Your application techniques directly influence curing duration—thin, even coats cure quicker, while thick layers delay the process. Additionally, environmental safety factors like temperature and humidity can affect curing times, especially for water-based formulas. Understanding curing processes is crucial for achieving optimal results and long-lasting protection. To guarantee the best results, follow manufacturer guidelines closely, considering these variables for safe handling and maximum durability. Proper curing guarantees a resilient finish and minimizes environmental impact.

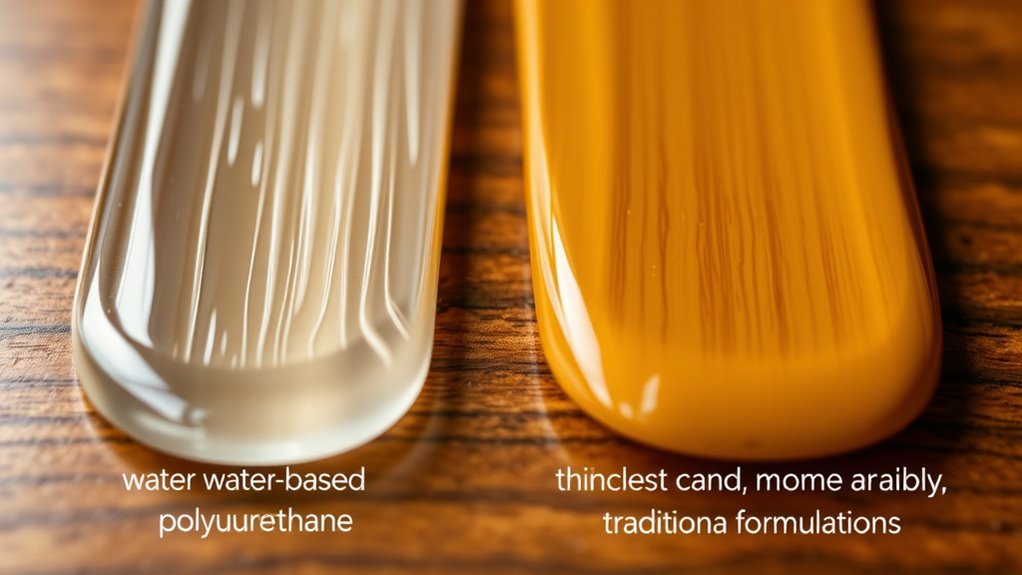

Appearance and Finish Quality

When comparing water-based and oil-based polyurethane, the appearance and finish quality are key factors to contemplate. Your choice impacts the look and feel of your project. Consider these points:

- Water-based polyurethanes offer clearer finishes with minimal amber tint, highlighting natural wood tones.

- Oil-based options tend to enhance warmth, giving a richer, amber hue over time.

- Sheen levels vary; water-based finishes typically provide a glossier look, while oil-based ones offer a softer sheen.

- Color options are limited for water-based polyurethanes but more diverse with oil-based products, affecting your aesthetic preferences.

- Understanding the differences in finish quality and appearance helps in selecting the best polyurethane for your project’s desired outcome.

Odor and Ventilation Requirements

Water-based polyurethane generally emits fewer fumes and has a milder odor compared to oil-based options, making it easier to work with in enclosed spaces. Because of its lower odor emissions, it typically meets stricter ventilation standards with less effort. You’ll notice that ventilation requirements for water-based products are less demanding, reducing the need for extensive airflow or specialized equipment. This makes it safer and more comfortable to apply indoors, especially in areas with limited ventilation. In contrast, oil-based polyurethane releases stronger fumes that require thorough ventilation to ensure safety and minimize odor buildup. Proper ventilation helps prevent health issues related to inhaling fumes and ensures a more pleasant work environment. Additionally, the exfoliating properties of glycolic acid can improve skin texture and pore appearance, making the overall application process more effective. Overall, odor and ventilation considerations are key factors when choosing between water-based and oil-based polyurethane.

Environmental Impact and Safety

Choosing between water-based and oil-based polyurethane directly impacts the environment and your safety. Water-based options generally emit fewer volatile organic compounds (VOCs), making them safer for indoor air quality and easier to comply with environmental regulations. Consider these safety considerations:

Water-based polyurethanes are safer and eco-friendlier due to lower VOC emissions and easier disposal.

- VOC emissions: Oil-based polyurethanes release higher VOC levels, which can cause health issues.

- Flammability: Oil-based products are more flammable during application.

- Toxicity: Solvent fumes pose risks if proper ventilation isn’t used.

- Disposal: Water-based polyurethanes are easier and safer to dispose of with less environmental impact.

Durability and Wear Resistance

Oil-based polyurethane typically offers superior durability and wear resistance compared to water-based options. Its high abrasion resistance means your floors or furniture will withstand heavy foot traffic and daily use longer. You’ll notice better scratch durability, which helps prevent surface dents and marks from impacts. This makes oil-based finishes ideal for high-traffic areas or surfaces prone to bumps. While water-based polyurethanes have improved over time, they generally don’t match the toughness of oil-based coatings in resisting wear and tear. If longevity and maintaining a pristine look are your priorities, oil-based products deliver a more durable, long-lasting finish. Keep in mind, though, that this durability often comes with longer drying times and stronger odors during application.

Cost and Availability

You’ll notice that water-based polyurethanes tend to be more affordable upfront, but prices can vary depending on your location. Oil-based options often cost more and may be harder to find in some regions. Considering both price differences and regional availability can help you choose the right product for your project.

Price Differences

Water-based polyurethane generally costs less upfront and is more readily available at most hardware stores compared to oil-based options. When doing a price comparison, you’ll notice that initial costs are lower, making it appealing for budget-conscious projects. To assess value:

- Consider the per-gallon price, often favoring water-based.

- Factor in the longer drying times of oil-based polyurethane, which might increase labor costs.

- Evaluate the need for thinner or cleaning solvents—more expensive for oil-based products.

- Think about durability and finish quality, which influence long-term value.

While oil-based polyurethane may have higher upfront costs, its durability could justify the price if longevity matters most. Ultimately, your choice depends on balancing initial expenses with long-term value.

Regional Availability

Where you live considerably impacts the availability and cost of polyurethane options. Regional preferences influence what’s more common, affecting market availability and pricing. In some areas, oil-based polyurethane dominates due to tradition, while water-based options are more accessible in others. Costs vary based on local suppliers and regulations, making certain types more affordable regionally. Here’s a quick overview:

| Region | Popular Type | Market Availability |

|---|---|---|

| North America | Oil-Based | Widely available, dominant |

| Europe | Water-Based | Increasingly popular, accessible |

| Asia | Oil-Based & Water-Based | Both options available, varies |

Knowing your regional preferences helps you choose the right polyurethane for your project, considering both cost and availability.

Maintenance and Repair

Maintaining and repairing polyurethane finishes is essential to preserving their appearance and durability over time. Proper surface prep is vital before any repair to ensure adhesion and a smooth finish. You should also consider environmental hazards like moisture, extreme temperatures, and UV exposure that can damage the coating. To keep your polyurethane in top shape, follow these steps:

Proper surface prep and environmental protection are key to maintaining durable polyurethane finishes.

- Clean the surface thoroughly to remove dirt and debris.

- Sand lightly to smooth out scratches or worn areas.

- Apply a compatible touch-up coat, ensuring proper surface prep.

- Protect the area from environmental hazards by controlling humidity and sunlight.

Regular inspection and timely repairs can extend the life of your polyurethane finish, whether water-based or oil-based.

Ideal Projects and Recommendations

Choosing the right polyurethane finish depends on your project’s specific needs and environment. Water-based polyurethane is ideal for projects where you want quick drying times, a clear finish, and minimal odor. It works well on furniture, cabinets, and decorative pieces that benefit from a natural look with subtle decorative effects. Its clear color options help maintain the original hue of your wood, especially if you want a light, modern appearance. Oil-based polyurethane, on the other hand, is better suited for high-traffic areas or items exposed to moisture, thanks to its durability and rich amber tone. It enhances decorative effects by deepening wood tones and providing a warm finish. Choose based on your desired aesthetic, durability, and environmental conditions for the best results.

Frequently Asked Questions

Which Type Is Better for Outdoor Furniture?

For outdoor furniture, you should consider durability and environmental impact. Oil-based polyurethane offers a tougher, more water-resistant finish, making it ideal for outdoor use. However, its application process is messier and it has a higher environmental impact due to fumes. Water-based polyurethane is easier to apply, dries quickly, and is eco-friendlier. Choose based on your priorities—long-lasting protection versus easier application and lower environmental footprint.

Can Water-Based Polyurethane Be Used Over Oil-Based Finishes?

Using water-based polyurethane over oil-based finishes is like mixing oil and water—seriously, it can cause compatibility concerns. You might see peeling, clouding, or uneven finishes if you disregard proper application techniques. To succeed, make certain the oil-based layer is fully cured and clean before applying water-based polyurethane. Patience and careful surface prep are key to avoiding disaster and achieving a smooth, durable finish.

How Do Different Polyurethane Types Affect Color Change Over Time?

You might notice that different polyurethane types impact color change over time through UV stability and gloss retention. Oil-based finishes tend to deepen colors and maintain gloss longer, but they may yellow with age. Water-based versions usually keep the original color more accurately and offer better UV stability, reducing discoloration. Your choice affects how your wood looks over the years, so consider these factors for long-term beauty and durability.

Is One Type More Suitable for Kitchen Countertops?

Imagine you’re stepping into a world where your kitchen counters are as resilient as a knight’s armor. For countertops, oil-based polyurethane often wins the durability comparison, standing up to heat, scratches, and moisture better. It’s essential to take into account application techniques, as oil-based finishes require proper ventilation and longer drying times. Water-based polyurethanes dry faster, but may not be as tough. Choose based on your need for durability and ease of application.

What Are the Long-Term Maintenance Differences Between Them?

When comparing long-term maintenance, consider the durability and environmental impact. Water-based polyurethane typically requires less frequent reapplication because it’s more resistant to wear over time, making it easier to maintain. Oil-based polyurethane, while more durable initially, can yellow and crack with age, needing more upkeep. It also has a higher environmental impact due to VOC emissions. Your choice affects how much effort and environmental concern your project will involve later on.

Conclusion

Choosing between water-based and oil-based polyurethane isn’t just about preferences—you’re about to discover which one truly transforms your project. Will the clear, quick-drying water-based option meet your needs, or does the rich, durable oil-based finish hold the secret to lasting beauty? Stay tuned, because the right choice could change everything, revealing unexpected benefits and surprises that could redefine your approach to finishing your surfaces. Are you ready to uncover the ultimate solution?