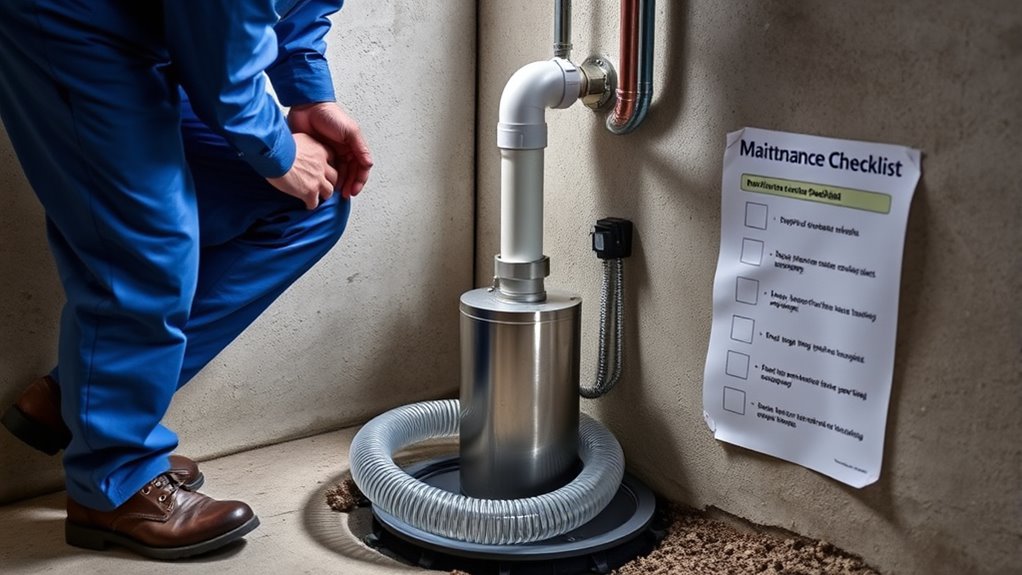

Before the rainy season, you should check your sump pump’s power source and backup battery to confirm they’re working well. Test the pump by adding water to see if it activates properly and drains quickly. Clear out the sump pit of debris and inspect the discharge line for blockages or damage. Also, verify that the float switch moves freely and the pump shows no signs of corrosion or wear. For more detailed tips, keep exploring how to safeguard your system effectively.

Key Takeaways

- Inspect electrical wiring, backup batteries, and perform professional system checks for proper safety and functionality.

- Test pump operation by adding water to ensure it activates smoothly and drains quickly.

- Clean the sump pit thoroughly, removing debris, leaves, and sludge to prevent blockages.

- Examine and clear the discharge line and float switch for cracks, blockages, and proper movement.

- Look for signs of corrosion or wear, address damages early, and schedule professional maintenance before heavy rain.

Inspect the Power Source and Backup System

Have you checked whether your sump pump’s power source is reliable? Start by inspecting the electrical wiring to verify it’s intact, free of corrosion, and properly connected. Faulty wiring can prevent your pump from activating during a power outage, so address any signs of wear or damage. Also, examine the battery health if you have a backup system. Make sure the backup battery is fully charged and holding a proper charge, as a weak or dead battery won’t provide essential backup during outages. Test the connections and replace any corroded or frayed wires. Regularly maintaining both the electrical wiring and backup battery guarantees your sump pump stays operational when you need it most, especially during heavy rain or power failures. Additionally, review the security zone info to ensure your system is protected from potential electrical hazards that could affect your sump pump’s performance.

Test the Pump’s Operation and Activation

To guarantee your sump pump works correctly, you need to test its response to water. Watch for smooth activation and confirm it starts pumping promptly. If it doesn’t respond properly, it’s time to troubleshoot or consider repairs. Regular maintenance can help prevent unexpected failures during critical times.

Check Pump Response

Wondering if your sump pump is working properly? To check its response, listen for pump noise when the water level rises. As water reaches the sump basin’s threshold, the pump should activate smoothly and quietly. If you notice excessive noise or nothing at all, it could indicate an issue. Watch the water level closely during testing—when it hits the trigger point, the pump should turn on promptly. Confirm the pump responds quickly and without hesitation. If it doesn’t activate as expected, further inspection may be needed. A responsive pump is essential for preventing flooding during heavy rain. Regularly testing its response helps verify it’s ready to handle rising water levels, giving you peace of mind before the rainy season arrives. Performing routine filter replacement and maintenance checks ensures the pump’s components are functioning properly and prolongs its lifespan.

Confirm Activation Properly

Ensuring your sump pump activates correctly is crucial for reliable performance. To confirm activation, pour water into the sump pit until the float rises and triggers the pump. Listen for the motor turning on and observe the water level lowering. This activation confirmation ensures your system is ready when heavy rains arrive. Additionally, periodically checking the headphone compatibility can help troubleshoot any issues with audio performance when using headphones for alerts or monitoring. | Step | What to Do | Why It Matters |

| ————————– | ——————————————– | ——————————— |

|---|---|---|

| Fill sump pit | Add water until pump activates | Tests system readiness |

| Listen for motor sound | Confirm pump runs smoothly | Detects potential motor issues |

| Observe water level | Water should drain quickly after activation | Ensures proper operation |

Perform this test regularly to keep your sump pump dependable, especially before the rainy season begins.

Clean Out the Sump Pit and Remove Debris

Start by removing the cover from the sump pit to gain easy access. Once open, use cleaning techniques to clear out any debris blocking the pump or clogging the pit. Regularly removing leaves, dirt, and other particles prevents debris buildup, which can hinder pump operation. To keep your sump pump working smoothly, consider these tips:

Begin by removing the sump pit cover and clearing out debris to ensure smooth pump operation.

- Use a sturdy brush or vacuum to remove sludge and dirt

- Inspect for small debris and pick out any obstructions

- Rinse the pit with water to wash away loose dirt

- Check that debris prevention barriers are intact to reduce future buildup

- Be aware of self-watering plant pots as an example of effective moisture management that can prevent over-saturation issues in some settings

Check the Discharge Line for Blockages or Damage

After clearing out debris from the sump pit, it’s important to examine the discharge line for any blockages or damage. A clogged discharge line can prevent water from flowing away properly, risking pump failure or water backup. Look for signs of blockage removal, such as water backing up or slow drainage. Check the entire length of the discharge line for kinks, cracks, or leaks. Clear any debris or ice buildup that might be obstructing the flow. If you find damage, replace or repair the line promptly to ensure proper drainage during heavy rain. Regular inspections help maintain your sump pump’s efficiency and prevent flooding. Additionally, digital literacy programs can help seniors better understand and maintain their sump systems. Taking these steps now can save you from costly repairs and water damage when the rainy season hits.

Examine the Float Switch for Proper Functionality

Start by ensuring the float moves freely without sticking or catching on anything. Next, test the switch to confirm it activates and deactivates at the right water levels. Finally, inspect for any debris or buildup that could hinder its proper operation. Additionally, consider regular inspections to maintain optimal sump pump performance.

Check Float Movement Smoothly

Ensuring your sump pump’s float switch moves smoothly is essential for reliable operation. If the float gets stuck or moves sluggishly, your pump might not activate when needed. Perform a simple movement check by lifting the float and observing its motion. It should rise and fall freely without resistance or obstruction.

Here are some tips for a proper float switch movement check:

- Gently lift the float to see if the pump kicks on

- Confirm the float doesn’t catch on debris or wires

- Check that the float reaches its highest and lowest points smoothly

- Ensure the switch resets easily after activation

A properly functioning float switch guarantees your sump pump operates correctly during heavy rain, preventing flooding.

Test Switch Activation Properly

To verify that your float switch activates your sump pump correctly, you need to perform a proper test of its functionality. First, locate the float switch inside the sump pit. Gently lift the float to simulate rising water levels and observe if the sump pump turns on. This is your activation check. If the pump doesn’t start, inspect the float switch for obstructions or damage. Make sure it moves freely without sticking. Once the pump activates, lower the float to ensure it turns off properly. Repeat the test a few times to confirm consistent operation. A properly functioning float switch ensures your sump pump responds accurately to water level changes, preventing flooding during heavy rains. Additionally, regularly inspecting the float switch mechanism can help identify potential issues before they lead to failure.

Inspect for Debris Buildup

Debris buildup around the float switch can hinder its proper operation, so it’s important to examine it regularly. When debris blocks the float, your drainage system might not activate correctly, risking flooding and damaging your sump pump’s lifespan. To keep it functioning smoothly:

- Clear leaves, dirt, and small debris from around the float switch

- Ensure nothing is obstructing its movement

- Check for signs of corrosion or grime buildup

- Test the switch manually to confirm it activates the sump pump

- Be aware that filtration systems help prevent debris from accumulating and interfering with the float switch.

Inspect the Pump for Signs of Wear or Corrosion

Regularly inspecting your sump pump for signs of wear or corrosion is essential to keep it functioning properly. Look for corrosion signs like rust or discoloration on metal parts, especially around the motor and impeller. Wear signs include cracks, leaks, or unusual noises during operation. Addressing corrosion prevention early can extend your pump’s lifespan and prevent costly repairs. Use the table below to identify potential issues:

| Issue | Warning Signs | Action Needed |

|---|---|---|

| Corrosion | Rust, discoloration | Clean, replace affected parts |

| Impeller Wear | Cracks, chips | Replace the impeller |

| Motor Components | Overheating, corrosion | Service or replace |

| Seal Failure | Leaks around shaft | Replace seal |

| Electrical Connections | Corrosion, loose wires | Tighten or replace wiring |

Regular inspections help catch problems early, ensuring your sump pump stays reliable. Proper maintenance also involves checking preventative measures that can minimize corrosion and wear over time.

Schedule Professional Maintenance and Repairs

Scheduling professional maintenance and repairs guarantees your sump pump operates at peak performance and reduces the risk of unexpected failures. Regular service ensures your system is ready for heavy rain and enhances your emergency preparedness. When you hire a professional, they can perform thorough inspections, identify hidden issues, and handle complex repairs beyond DIY troubleshooting.

Consider these benefits:

- Detecting early signs of wear or damage

- Ensuring proper float switch operation

- Checking backup systems for added safety

- Saving time and avoiding costly repairs

Even if you’re comfortable with DIY troubleshooting, professional maintenance offers peace of mind. It keeps your sump pump reliable and ready to handle heavy rain, protecting your home and belongings when it matters most.

Frequently Asked Questions

How Often Should I Perform Sump Pump Maintenance Before the Rainy Season?

You should perform a routine inspection of your sump pump at least once a year, ideally before heavy rains begin. During this inspection, remove any debris from the pump and check that it’s functioning properly. If you experience frequent storms or your pump is older, consider more frequent checks, like every 3 to 6 months. Keeping your sump pump well-maintained guarantees it operates efficiently when you need it most.

What Are Common Signs My Sump Pump Needs Replacement?

You should watch for signs your sump pump needs replacement, especially considering its lifespan and pump failure indicators. If your pump makes unusual noises, runs constantly, or doesn’t turn on during heavy rain, these are warning signs. Also, if it’s over 8-10 years old, its efficiency may decline. Regularly testing it helps catch issues early, ensuring you won’t be caught off guard during a storm.

Can I Install a Backup Sump Pump System Myself?

Imagine building a safety net before a big storm—you can try a DIY installation for your backup sump pump system, but it’s like assembling a complex puzzle. If you’re handy and follow detailed instructions, you might succeed. However, a backup system requires careful wiring and fitting; mistakes could lead to flooding. When in doubt, hiring a professional guarantees your backup system works reliably when you need it most.

How Do I Prevent Freezing of the Sump Pump in Winter?

To prevent freezing of your sump pump in winter, you should focus on freezing prevention and winter insulation. Make sure to insulate the sump pit with foam or insulated covers to keep cold air out. Additionally, verify the discharge line is properly insulated and slopes away from your home. Running a small amount of water through the pump occasionally also helps prevent freezing, especially during extremely cold temperatures.

What Safety Precautions Should I Take During Maintenance?

When performing sump pump maintenance, you should always unplug the device first to avoid electric shock. Wear rubber gloves and use insulated tools for safety. Keep the area dry to prevent fire hazards, and never work near water or electrical outlets with wet hands. Regularly check for damaged cords or parts that could cause sparks. Following these precautions guarantees your safety while maintaining your sump pump effectively.

Conclusion

By taking these simple steps, you’ll turn your sump pump into an unstoppable flood-fighting superhero, ready to conquer even the most torrential rains. Skip maintenance, and it’s like inviting a tiny leak to turn your basement into a swimming pool! Don’t let a small problem turn into a giant flood—give your sump pump the superhero treatment now, and sleep easy knowing you’re prepared for whatever Mother Nature throws your way.