To keep your booster pump in good shape, regularly inspect key components like the motor, control panel, and wiring for leaks, corrosion, or wear. Clean or replace filters, lubricate moving parts, and check seals and gaskets to prevent leaks. Monitor pressure and flow rates, and troubleshoot issues such as noise or vibrations promptly. Scheduling professional servicing helps catch problems early and extends your pump’s lifespan—continue for more tips on maintaining peak performance.

Key Takeaways

- Regularly inspect the pump motor, control panel, and electrical wiring for signs of wear, corrosion, leaks, or damage.

- Clean and replace filters, and lubricate bearings and shafts following manufacturer guidelines to ensure smooth operation.

- Monitor pressure gauges and flow rate sensors to detect system issues before they cause damage.

- Troubleshoot common problems like noise, vibrations, or startup failures by checking connections, alignment, and component wear.

- Schedule professional servicing annually or when issues arise to maintain optimal performance and extend pump lifespan.

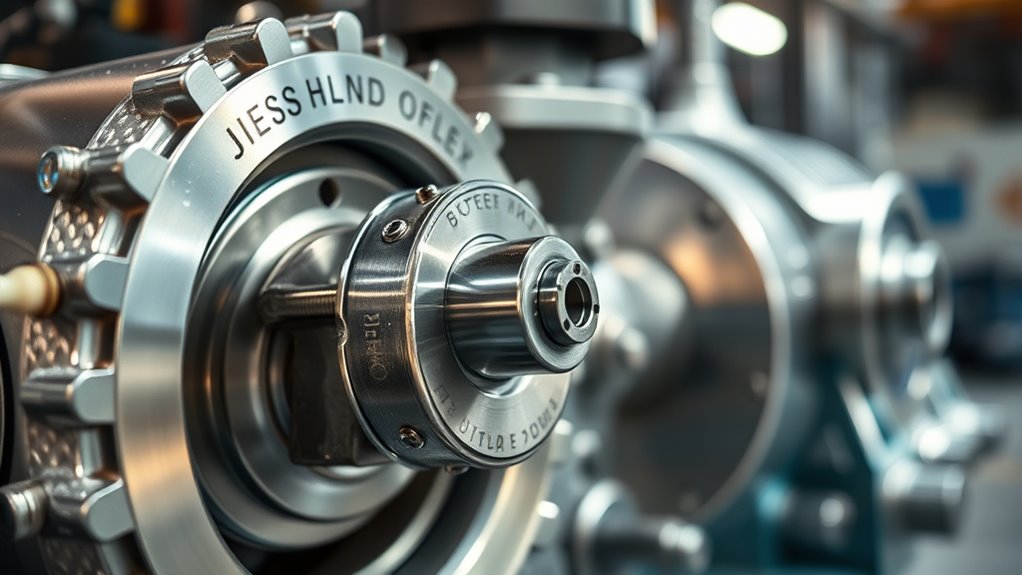

Understanding Your Booster Pump’s Components

Understanding the components of your booster pump is essential for proper maintenance and troubleshooting. The pump motor is the heart of the system, providing the power needed to pressurize the water. You should regularly check that the motor runs smoothly, without unusual noises or vibrations, which could indicate issues. The control panel is your interface for managing the pump’s operation. It contains important controls and indicator lights that help you monitor system status, such as pressure levels and electrical connections. Familiarizing yourself with these components allows you to quickly identify potential problems and guarantee your booster pump operates efficiently. Regularly inspecting both the pump motor and control panel helps prevent failures, saving you time and costly repairs down the line. Additionally, understanding the maintenance requirements for your pump ensures optimal performance and longevity. Incorporating routine inspection of all parts can help detect early signs of wear and tear, further extending the lifespan of your pump. Being aware of system performance metrics can also aid in maintaining optimal operation and early troubleshooting. Recognizing the importance of component compatibility can help ensure that replacement parts fit properly and function as intended. Moreover, understanding compatible replacement parts can facilitate smoother repairs and upgrades, reducing downtime.

Regular Inspection and Visual Checks

Regular inspection and visual checks are vital to keep your booster pump running smoothly. Regularly examine the pump for signs of pipe corrosion, which can lead to leaks or failures. Check the electrical wiring for wear, fraying, or loose connections to prevent electrical issues. Keep an eye out for leaks around seals and fittings, and ensure the pump is free of debris. Additionally, monitoring for cognitive impairment can help identify early signs of issues that may affect operation, especially in environments with senior personnel. Consider these key checks: – Inspect pipes for corrosion or rust – Examine electrical wiring for damage – Look for leaks or abnormal noises. Incorporating preventive maintenance practices, such as scheduled cleaning and component testing, can further extend the lifespan of your equipment. Regularly testing the pump’s performance metrics can help detect potential problems before they escalate. To maintain optimal efficiency, it is also important to keep an eye on the internal components, ensuring they are functioning correctly and are free of wear. A visual inspection of fabric decorating markers can help verify their colorfastness and suitability for projects. Perform these checks monthly to catch problems early. Address any corrosion, wiring issues, or leaks immediately to maintain efficiency and prevent costly repairs. Staying proactive with visual checks keeps your booster pump reliable.

Cleaning and Maintaining Filters

Cleaning and maintaining your filters is essential to guarantee your booster pump operates efficiently and reliably. Regular filter replacement ensures debris doesn’t clog the system, which can cause strain or damage. Start by turning off the pump and relieving pressure before removing the filters. Carefully inspect them for dirt, debris, or signs of wear. For debris removal, rinse filters with clean water, using a soft brush if necessary to loosen stubborn particles. If filters are damaged or excessively dirty, replace them immediately to maintain peak performance. Keep a schedule for filter checks—monthly or as recommended by the manufacturer. Well-maintained filters prevent blockages, reduce pump strain, and extend your booster pump’s lifespan. Incorporating proper Porsche Tuning practices can optimize your vehicle’s performance and longevity. Staying on top of filter care saves you from costly repairs and downtime. Regular maintenance also supports the overall system efficiency, and understanding the importance of filter quality can help you choose the best replacements and improve your maintenance routine. Additionally, adopting data-driven strategies for maintenance schedules can help you identify optimal times for checks and replacements, further enhancing system reliability.

Lubricating Moving Parts

Lubricating the moving parts of your booster pump is essential to guarantee smooth operation and prevent unnecessary wear. Regular lubrication ensures that components like bearings and shafts move freely, reducing friction and extending lifespan. Check the oil levels frequently and follow the lubrication schedules recommended by the manufacturer. Proper lubrication also helps avoid overheating and noise issues. To keep your pump in top shape, consider these tips:

- Use the correct type of oil specified in your pump’s manual

- Apply lubricant at scheduled intervals to avoid neglect

- Inspect moving parts regularly for signs of wear or inadequate lubrication

- Staying informed about best maintenance practices can further enhance your pump’s longevity.

- Additionally, being aware of support hours can help you get assistance promptly if issues arise.

- Regularly monitoring lubrication effectiveness ensures optimal performance and prevents potential damage. Proper lubrication procedures are supported by understanding the function of bearings, which are critical components that facilitate smooth rotation and reduce friction.

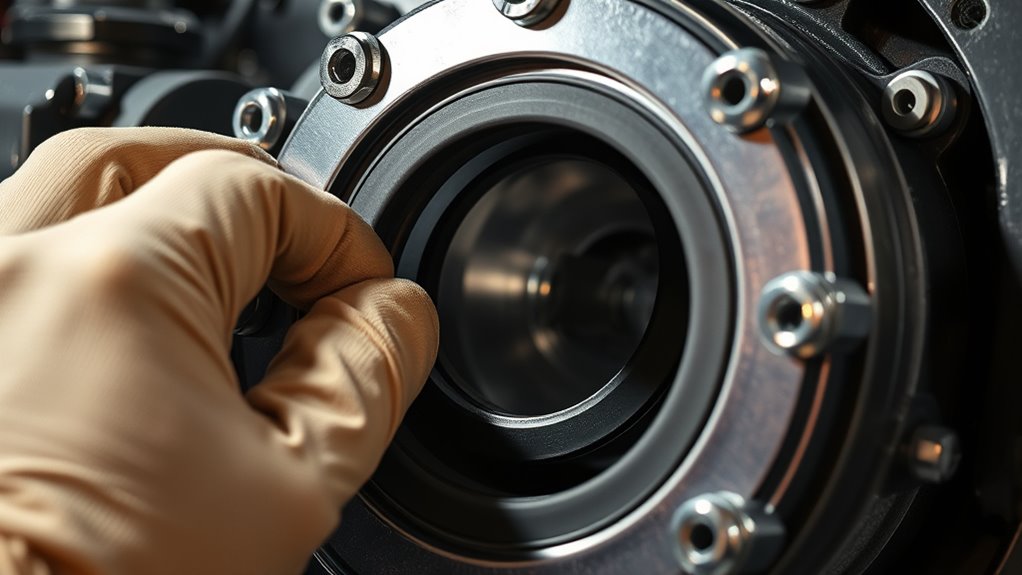

Checking and Replacing Seals and Gaskets

Have you checked the seals and gaskets on your booster pump lately? Regular seal replacement and gasket inspection are essential to prevent leaks and maintain efficiency. Worn or damaged seals can cause pressure drops, while degraded gaskets may lead to water leaks. Additionally, inspecting the air purifier filters periodically can help ensure optimal performance and air quality. Use the table below to guide your inspection:

| Task | Important Tip |

|---|---|

| Seal replacement | Replace if cracked or brittle |

| Gasket inspection | Look for cracks or deformation |

| Reinstallation | Ensure proper sealing |

Perform these checks periodically, especially if you notice unusual noises or drops in performance. Replacing seals and inspecting gaskets on time can save you costly repairs and keep your booster pump running smoothly. For better longevity, consider using durable materials when replacing components, especially those that are exposed to environmental stressors. Also, regular maintenance of pump components can help prevent deterioration and extend the lifespan of your equipment.

Monitoring Pressure and Flow Rates

Monitoring pressure and flow rates is crucial for guaranteeing your booster pump operates efficiently and reliably. Regularly check your pressure gauge calibration to confirm accurate readings, which helps prevent over-pressurization or pressure drops. Use flow rate sensors to monitor how much water is moving through the system, allowing you to detect issues early. Keep an eye on these key points:

- Make sure pressure gauges are calibrated correctly for precise readings

- Use flow rate sensors to track water flow consistency

- Record pressure and flow data regularly for trend analysis

- Incorporate Ford Tuning techniques to optimize your system’s performance and longevity.

- Staying informed about AI vulnerabilities can help you implement additional safety measures to protect your system from potential cyber threats. Additionally, understanding system diagnostics can aid in troubleshooting and maintaining system health over time.

- Staying updated on automation advancements can help you integrate new technologies for improved system efficiency.

Troubleshooting Common Issues

If your booster pump isn’t starting, check the power supply and wiring connections first. Unusual noises or vibrations often indicate loose parts or bearing issues that need inspection. Addressing these common problems promptly can keep your pump running smoothly.

Pump Not Starting

Is your booster pump refusing to start when you need it most? This can be frustrating, but often it’s linked to simple issues like the installation setup or the pump’s lifespan. First, check that power connections are secure and the circuit breaker hasn’t tripped. Ensure the pump is properly wired and grounded. A worn-out pump or one nearing the end of its lifespan might struggle to start.

To troubleshoot, consider these steps:

- Verify the electrical supply and reset any tripped breakers

- Inspect the wiring and connections for damage

- Evaluate if the pump has been in use for a long time and may need replacement

Keeping these factors in mind helps prevent startup issues and keeps your booster pump running smoothly.

Unusual Noises or Vibrations

Unusual noises or vibrations from your booster pump often signal underlying problems that need quick attention. Vibration analysis helps identify the root cause, such as misalignment, worn bearings, or loose components. If you hear banging, humming, or rattling, inspect the pump for loose fittings or debris, and tighten or remove obstructions. To reduce noise and vibrations, consider noise mitigation techniques like installing vibration isolators or rubber mounts. Regularly check for uneven wear or imbalance in the impeller or motor. Addressing these issues promptly prevents further damage and prolongs your pump’s life. Remember, persistent vibrations can compromise the pump’s efficiency, so don’t ignore unusual sounds—investigate immediately to keep your system running smoothly.

Scheduling Professional Servicing

When should you schedule professional servicing for your booster pump? Ideally, you should do it annually or if you notice issues like inconsistent pressure or unusual noises. Regular maintenance helps ensure peak pump calibration and verifies that electrical wiring is secure and functioning properly.

During service, a technician will:

- Perform pump calibration to maintain efficiency

- Inspect and tighten electrical wiring for safety

- Check for wear and tear on components

Scheduling proactive maintenance prevents unexpected breakdowns and prolongs your pump’s lifespan. Keep a maintenance log to track service dates and issues. Addressing minor concerns early saves you money and avoids major repairs later. Regular professional servicing guarantees your booster pump operates reliably and efficiently.

Frequently Asked Questions

How Often Should I Replace My Booster Pump’s Parts?

You should replace your booster pump’s parts based on their wear and tear, typically every 1-3 years. Regular pump lubrication helps prevent premature failure, so keep an eye on moving parts. Consider system upgrades when you notice decreased performance or increased energy use. Regular inspections ensure components stay in good condition, extending the pump’s lifespan and maintaining efficiency. Always follow manufacturer guidelines for specific replacement intervals.

What Are Signs of Imminent Booster Pump Failure?

You should watch for signs of imminent booster pump failure like unusual pump noise or vibration issues. If the pump starts making loud or irregular sounds, it indicates potential problems. Vibration issues, especially if they increase or become constant, also signal that something’s wrong. Address these signs promptly to prevent complete failure, which can lead to costly repairs or system downtime. Regular inspections help catch these issues early.

Can I Upgrade My Booster Pump for Better Performance?

If you’re considering upgrading your booster pump for better performance, you can definitely explore options. Look for models with quieter operation to reduce pump noise and higher efficiency. Check your pressure gauge to guarantee the new pump meets your system’s pressure requirements. Upgrading can improve flow and reliability, but make sure the new pump is compatible with your existing setup. Consulting a professional can help you choose the best upgrade.

How Does Temperature Affect Booster Pump Operation?

Sure, temperature’s just a tiny detail, right? Well, it actually impacts your booster pump more than you’d think. As temperatures rise, thermal expansion can cause components to expand, stressing the system. Conversely, cold ambient conditions might make parts less efficient or even freeze. So, keeping an eye on temperature guarantees your pump runs smoothly, preventing unexpected breakdowns and maintaining ideal performance regardless of thermal surprises.

Is There a Way to Prevent Pump Corrosion Naturally?

To prevent pump corrosion naturally, you can use corrosion prevention methods like adding natural corrosion inhibitors such as vinegar or citrus extracts to the water. Regularly inspecting your pump and keeping it dry helps prevent rust. Also, guarantee the water’s pH level stays balanced, as acidic or alkaline conditions accelerate corrosion. These natural methods are eco-friendly and cost-effective, extending your pump’s lifespan without relying on harsh chemicals.

Conclusion

By understanding your booster pump’s components, inspecting it regularly, cleaning filters, lubricating parts, and monitoring performance, you guarantee its longevity and efficiency. Address issues promptly, replace worn seals, and schedule professional servicing when needed. Keep these steps in mind, stay proactive, stay attentive, and stay confident in your pump’s performance. With consistent maintenance, you’ll prevent breakdowns, extend its lifespan, and keep your system running smoothly—because a well-maintained booster pump is a reliable booster pump.