To avoid deck sealing mistakes, start by properly cleaning and prepping your surface, and always follow the manufacturer’s instructions. Don’t apply sealer in bad weather or rush drying times, as this weakens the bond. Use compatible products and apply them evenly in thin coats. Keep an eye on reapplication schedules and maintain regular upkeep. Staying aware of these key tips will help your deck stay protected and looking great longer.

Key Takeaways

- Properly clean, dry, and follow manufacturer instructions for surface preparation before sealing your deck.

- Use compatible sealants and apply with appropriate tools in suitable weather conditions.

- Allow sufficient drying and curing time between coats and before placing furniture or walking on the deck.

- Apply a thin, even coat of sealer and avoid over- or under-application for optimal protection.

- Regularly monitor, reapply as recommended, and consider seasonal factors to maintain deck durability and appearance.

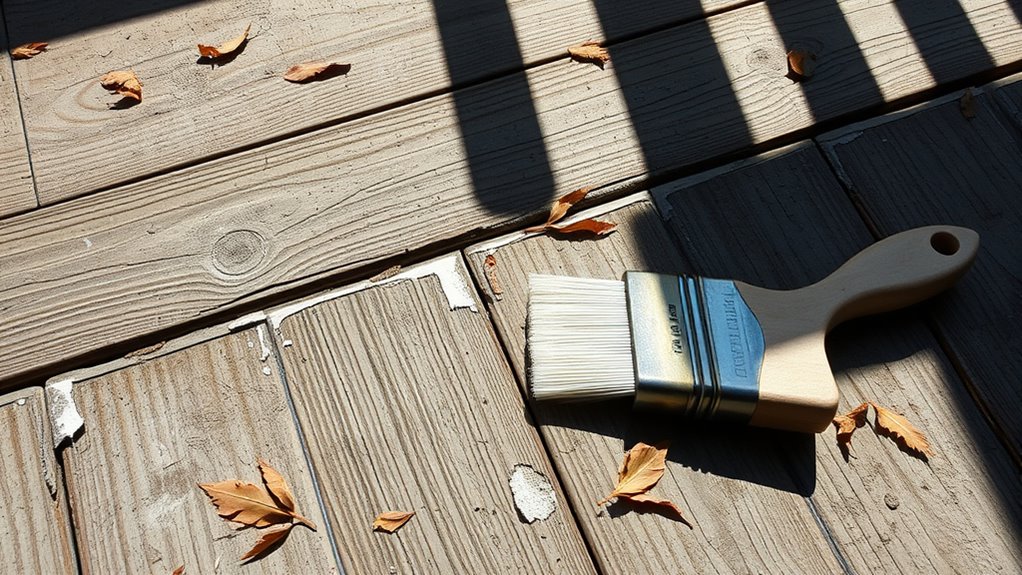

Neglecting Proper Surface Preparation

Neglecting proper surface preparation can lead to serious problems down the line. Before sealing your deck, you must focus on thorough surface cleaning to remove dirt, mold, and debris that can prevent proper adhesion. Skipping this step causes the sealant to bond poorly, reducing its effectiveness and lifespan. After cleaning, applying a primer is vital; it creates a smooth, compatible surface for the sealant and enhances adhesion. Without primer application, the sealant may peel or deteriorate prematurely. Always guarantee the deck is completely dry and free of loose particles before applying primer. Taking these steps might seem simple, but they form the foundation for a long-lasting seal. Proper surface preparation prevents future issues and saves you time and money on repairs.

Choosing the Wrong Sealing Product

Choosing the right sealing product is vital because using the wrong type can compromise your deck’s durability and appearance. To guarantee effectiveness, consider sealant compatibility with your deck’s surface and environment. Using incompatible sealants can lead to peeling, uneven coverage, or damage over time. Additionally, selecting the appropriate application tools is essential for a smooth, even coat—brushes, rollers, or sprayers should match the product’s consistency. Skipping this step may result in uneven sealing or wasted material. Always read manufacturer instructions carefully to confirm the sealant suits your deck type and weather conditions. Proper sealant application ensures optimal protection and longevity for your deck. Making informed choices about the sealant and application tools helps you avoid costly mistakes and extends your deck’s lifespan.

Applying Sealer in Inappropriate Weather Conditions

Applying sealer when weather conditions are unsuitable can considerably undermine your deck’s protection and longevity. Weather considerations are vital for a successful seal coat, as high humidity, rain, or extreme temperatures can prevent proper adhesion and drying. Seasonal timing also plays a significant role; sealing during cold or wet seasons hampers the curing process and may cause the sealer to peel or become cloudy. Ideally, choose a period with mild, dry weather—typically in spring or early fall—to guarantee optimal results. Avoid applying sealer during extreme heat, which can cause quick drying and uneven coverage, or during rain, which can wash away or dilute the product. Proper planning around weather conditions helps your sealant perform as intended, extending your deck’s lifespan. Additionally, understanding projector technology can help you select the right equipment for your home cinema setup.

Skipping the Necessary Drying and Curing Time

Even if the sealer appears dry to the touch, rushing the drying and curing process can compromise the results. Skipping or shortening the necessary drying process means the sealer hasn’t fully set, leaving your deck vulnerable to damage or staining. The curing duration is vital because it allows the sealer to harden properly and develop maximum durability. If you walk on or place furniture on the deck too soon, you risk ruining the finish or creating uneven spots. Be patient and follow the manufacturer’s instructions for drying time. Waiting the full curing duration ensures the sealer bonds correctly with the wood, providing long-lasting protection. Proper curing also helps prevent issues like moisture damage and ensures the sealer maintains its appearance over time. Rushing this step can undo all your effort and lead to costly repairs or re-sealing down the line.

Over- or Under-Applying the Sealer

Applying too much sealer can lead to puddles and a sticky surface, while too little may leave your deck unprotected. Both mistakes can cause uneven coverage and reduce the sealer’s effectiveness. To get it right, use proper techniques and follow the manufacturer’s instructions carefully. Additionally, understanding Mazda Tuning techniques can teach you the importance of precise application to optimize results.

Excess Sealer Risks

Using too much sealer can create problems, just as under-applying it can. Excess sealer can hinder proper sealer penetration, preventing the product from soaking into the wood effectively. This often results in a sticky, uneven surface that may trap dirt and moisture, leading to future damage. Over-application also impacts surface adhesion, causing the sealer to peel or flake prematurely. When you apply too much, it creates a thick film that doesn’t bond well, reducing the deck’s protection. To avoid these issues, follow the manufacturer’s instructions carefully and apply a thin, even coat. Proper application ensures adequate sealer penetration and strong surface adhesion, extending the life of your deck and maintaining its appearance. Remember that butter’s artistic influence demonstrates how material properties like malleability and color can be harnessed effectively when used correctly, highlighting the importance of proper application techniques.

Insufficient Coverage Issues

Applying too little or too much sealer can leave your deck vulnerable to damage. When coverage is insufficient, the deck’s texture isn’t properly sealed, exposing it to moisture and UV damage. To avoid this, keep in mind:

- Use the right sealing tools to guarantee even application across different deck textures.

- Apply sealant in thin, consistent coats, avoiding puddles or missed spots.

- Regularly check coverage, especially in textured areas like grooved boards or uneven surfaces.

Proper Application Techniques

Over- or under-applying sealer can critically weaken your deck’s protection, so it’s vital to get the technique right. Start by thoroughly surface cleaning to remove dirt, mold, and old sealant, ensuring proper adhesion. When selecting a product, choose one designed for your deck’s material and follow the manufacturer’s instructions carefully. Use the right tools, like brushes or rollers, to apply the sealer evenly, avoiding puddles or missed spots. Maintain a consistent application thickness—too thick can cause peeling, while too thin offers inadequate protection. Work in manageable sections, and don’t rush the process. Proper surface cleaning and product selection lay the foundation, but applying the sealer evenly and correctly guarantees your deck stays protected and looks great for years. Understanding the horsepower of electric dirt bikes can help you choose the right equipment if you plan to do some outdoor maintenance or projects around your property.

Ignoring Regular Maintenance and Reapplication Schedule

Failing to stick to a regular maintenance and reapplication schedule can considerably shorten the lifespan of your deck sealant. To avoid this, you need effective timing strategies and consistent maintenance routines. Here’s what you should focus on:

Neglecting regular maintenance shortens your deck sealant’s lifespan—stay proactive with timely reapplications and inspections.

- Monitor weather conditions – reapply sealant when rain or humidity increase, typically every 1-3 years.

- Inspect your deck regularly – look for signs of wear, peeling, or fading that indicate it’s time for re-sealing.

- Follow manufacturer recommendations – adhere to suggested reapplication intervals to maintain protection and appearance.

- Track your maintenance history – keeping a record helps ensure you follow the optimal reapplication schedule and avoid neglecting necessary upkeep.

Frequently Asked Questions

How Often Should I Reseal My Deck for Optimal Protection?

You should reseal your deck every 1 to 3 years for ideal protection. Regular deck maintenance includes following a proper sealing schedule to prevent damage from weather and wear. Keep an eye on your deck’s condition, and if it starts looking dull or shows signs of wear, it’s time to reseal. Consistent sealing helps extend your deck’s lifespan and keeps it looking great.

Can I Seal My Deck if It’s Already Damaged or Stained?

Can you seal your deck if it’s damaged or stained? Think of it like trying to paint a crumbling wall—you’re wasting effort! Damaged decks won’t hold sealant properly, and stains can seep through, making the project pointless. Before sealing, you must repair deck damage and perform stain removal. Otherwise, your efforts are just a fancy bandaid on a broken problem, and the damage will only worsen over time.

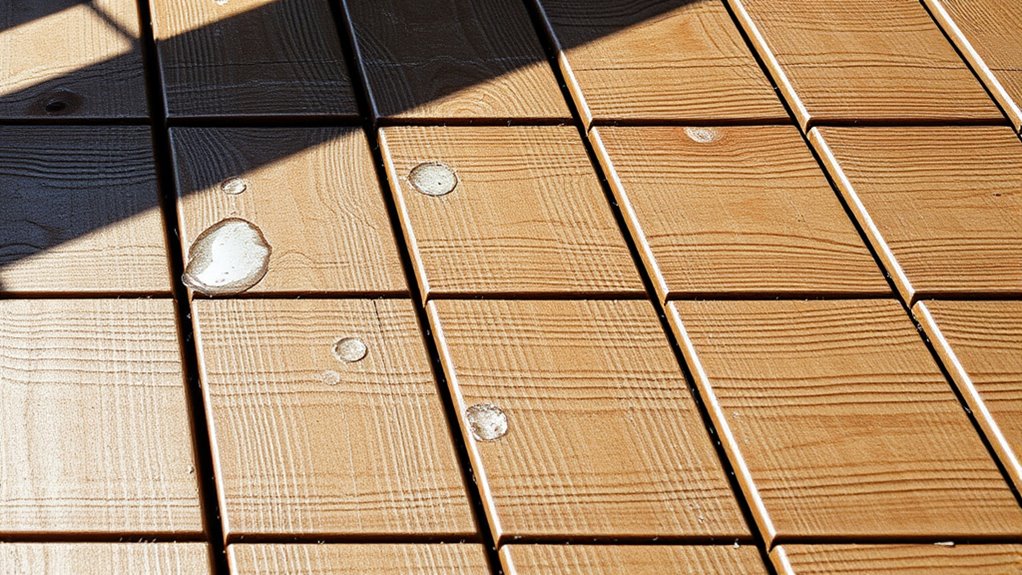

What Are the Signs That My Deck Needs Sealing?

You’ll know your deck needs sealing if you notice signs like deck discoloration, which dulls its appearance, or surface splinters that make walking barefoot uncomfortable. If water no longer beads on the surface or absorbs quickly, it’s a clear sign the sealant has worn off. Regularly inspecting these signs helps you maintain your deck’s durability and appearance, ensuring it stays protected and inviting for years to come.

Is It Necessary to Sand or Strip Old Sealant Before Resealing?

You should sand or strip old sealant before resealing to guarantee proper surface preparation. This step removes peeling or deteriorated sealant, creating a smooth, clean surface that promotes better adhesion. It also helps prevent issues with sealant compatibility, which can cause peeling or bubbling if old layers remain. Taking time to prepare your deck properly ensures the new sealant bonds well, providing longer-lasting protection and a professional finish.

How Do Temperature Fluctuations Affect the Sealing Process?

Temperature fluctuations can substantially impact the sealing process. When temperatures vary, they cause temperature expansion and contraction of the deck surface, which can stress the sealant. If you apply sealant during extreme heat or cold, it may lose flexibility and crack as the deck expands and contracts. To guarantee a durable seal, choose a flexible sealant suitable for your climate and apply it within recommended temperature ranges.

Conclusion

By avoiding these common deck sealing mistakes, you’re like a skilled artist perfecting every stroke—ensuring your deck’s beauty and longevity shine through. Think of proper prep, weather, and patience as the brush and palette that bring your outdoor masterpiece to life. When you pay attention to these details, your deck will withstand the test of time, standing tall like a fortress of durability. Master these secrets, and your deck will be the crown jewel of your backyard oasis.