When choosing a drill, understanding voltage and torque is vital. Voltage affects power; for light tasks, opt for 9-14 volts, while heavier jobs require 18-24 volts for more torque. Torque measures rotational force, essential for handling different materials—higher torque is better for dense ones. A good drill balances comfort and power, and understanding these features helps you pick the right tool for your projects. There’s more to uncover about drill features to guarantee you make the best choice.

Key Takeaways

- Choose drill voltage based on project complexity; lower voltages (9-14V) suit basic tasks, while higher voltages (18-24V) handle demanding jobs.

- Torque, measured in Newton meters, determines the drill’s ability to drive screws and handle various materials effectively.

- Adjustable torque settings enhance versatility, allowing you to prevent damage to materials and ensure proper screw fastening.

- Corded drills offer consistent power for heavy-duty tasks, while cordless drills provide mobility but may slow down with low battery.

- Brushless motors are more efficient and have longer lifespans than brushed motors, making them ideal for demanding applications.

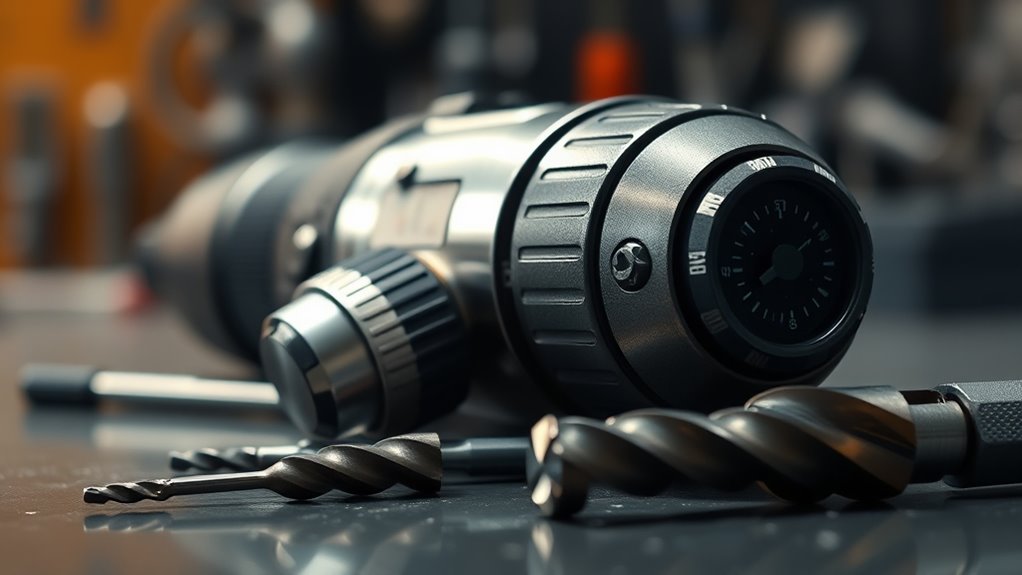

Importance of Voltage in Power Drills

When choosing a power drill, understanding voltage is vital. The voltage rating directly impacts the drill’s power and suitability for various tasks. Typically, cordless drills range from 4 to 20 volts.

Understanding the voltage of a power drill is crucial for determining its power and task suitability.

If you’re tackling light-duty jobs, a 12V drill will suffice for tasks like hanging pictures. However, for heavy workloads—think drilling through hardwood or metal—opt for an 18V or 20V model. Routine health checks can help ensure that your drill is functioning at its best, similar to how regular health assessments for pets can prevent issues. Additionally, many high-voltage models come with specialized attachments for enhanced performance across different materials. For instance, a higher voltage drill can provide enhanced performance when using specialized bits. A well-chosen drill can also improve energy efficiency during extended use, reducing strain on the battery.

Higher voltage drills usually come with larger batteries, making them heavier and potentially less portable for extended use. Additionally, they often offer more settings and attachments, increasing versatility for your projects.

While voltage is significant, don’t forget to take into account battery capacity and the drill’s efficiency to guarantee peak performance. Understanding voltage can also help you select the right drill for your specific needs.

How Torque Relates to Drill Performance

Torque plays an essential role in determining how well your drill performs, especially when dealing with different materials. Measured in Newton meters (Nm), torque indicates the rotational force your drill can exert.

When you select a torque setting, lower numbers mean less power, while higher numbers provide more torque before disengagement. Understanding the relationship between torque and the material is critical; soft materials need lower torque to prevent damage, while dense materials require higher torque for effective drilling.

Using the maximum power setting can enhance performance by bypassing the clutch, delivering peak torque for tougher tasks. Choosing a drill with appropriate torque ratings guarantees you meet your project’s demands, boosting productivity and minimizing the risk of mishaps.

Cordless vs. Corded Drills: Power Considerations

When choosing between cordless and corded drills, you’ll notice key differences in power consistency and mobility.

Corded drills offer reliable power without the worry of battery life, making them great for heavy-duty tasks, while cordless models provide freedom of movement but may slow down as batteries drain. Additionally, understanding the impact of torque can help you choose the right drill for your specific projects. Proper installation and maintenance of your tools can also ensure their longevity and optimal performance. To maximize your drill’s effectiveness, consider how the right tea kettle can influence your overall experience with tools that involve heat, such as soldering or heating elements. Choosing the appropriate tool, such as an airless paint sprayer, can further enhance your efficiency for painting projects. Moreover, modern energy-efficient fans can contribute to a more pleasant workspace by improving airflow during your projects.

Consider how these factors align with your project needs to make the best choice.

Power Consistency Comparison

While both corded and cordless drills can offer impressive power ratings, their performance consistency varies considerably.

Corded drills provide a steady power supply without the worry of recharging, making them perfect for long tasks. In contrast, cordless drills often lose power as their batteries deplete, which can hinder your work, especially in demanding applications. Additionally, advanced filtration systems in cordless models can help maintain performance for longer durations. Many users find that high-voltage batteries significantly improve the efficiency of their cordless tools.

Though high-voltage cordless drills (18V or more) can handle tougher jobs, they still risk a drop in performance when the battery charge is low. Additionally, corded drills generally deliver greater torque for heavy-duty tasks, thanks to their direct power source.

If you need reliable, consistent power for extensive projects, corded drills might be the better choice. Furthermore, understanding battery performance characteristics can help you select the right drill for your needs.

Mobility and Weight Factors

Choosing between corded and cordless drills often comes down to mobility and weight, as these factors can greatly impact your workflow.

Cordless drills generally range from 4 to 18 volts, with higher voltage models delivering more power but also adding weight, which can be cumbersome during extended use. If you need a drill for demanding tasks, a higher voltage cordless option is your best bet. However, for light-duty jobs around the house, a lower voltage model, like 12V, is perfect. Modern heat pumps designed with quieter operation in mind can enhance comfort and make for a more pleasant working environment. Additionally, air purifiers can help maintain a cleaner workspace by reducing airborne particles. Creating a clutter-free space is essential for a productive work environment. Furthermore, it’s important to consider the potential state tax implications associated with withdrawing funds from retirement accounts for purchasing tools, as this can influence your overall budget.

On the other hand, corded drills offer consistent power without worrying about battery life, but you’re limited by the power cord, which can restrict mobility. Additionally, it’s important to consider the environmental impacts of tool usage, as sustainable practices can help reduce overall energy consumption.

Ultimately, balance your power needs with comfort for peak productivity.

Understanding Battery Capacity and Runtime

When you’re choosing a cordless drill, understanding amp-hour ratings is essential for gauging runtime.

A higher Ah rating means you’ll get more use before needing a recharge, but it can also add weight to your tool. Incorporating a balanced diet can help maintain your energy levels, ensuring you stay focused during your projects. Balancing the battery’s power with its weight guarantees you stay comfortable during your projects. Additionally, music therapy can be a great way to alleviate stress while working on your tasks. It’s also important to consider fresh orange juice as a refreshing drink that can keep you hydrated while you work. Choosing a drill with energy-efficient models can also enhance your overall efficiency and prolong battery life. Understanding user consent management is crucial for ensuring that you are aware of how data is handled during your online shopping experience.

Amp-hour Ratings Explained

Amp-hour (Ah) ratings are essential for understanding a battery’s capacity and runtime.

These ratings help you determine how long your cordless drill will operate before needing a recharge. Here’s what you need to know:

- A 2 Ah battery runs a device drawing 2 amps for 1 hour.

- A 4 Ah battery can power the same device for up to 2 hours.

- Higher Ah ratings mean increased weight, impacting tool balance and portability.

- When choosing a drill, consider both voltage for power and Ah ratings for duration.

Impact on Runtime

Understanding how battery capacity affects runtime is essential for getting the most out of your cordless drill.

Battery capacity, measured in ampere-hours (Ah), directly influences how long you can work before needing a recharge. For example, a 2Ah battery lasts half as long as a 4Ah battery under the same load.

Higher voltage drills, like 18V or 20V models, can handle tougher tasks but often require larger batteries, which can impact runtime.

Additionally, the material you’re drilling matters; denser materials demand more power, draining the battery faster. Moreover, just as herbal remedies can vary in effectiveness based on their preparation, the load and conditions under which the drill operates significantly affect battery performance.

Balancing Weight and Power

While you might prioritize power when selecting a cordless drill, it’s essential to take into account the weight of the battery as well. Balancing these factors can greatly influence your performance and comfort.

Here are a few key points to reflect on:

- Higher ampere-hour (Ah) ratings provide longer runtime, ideal for extensive projects.

- Lighter batteries may enhance comfort but might limit power on demanding tasks.

- Higher voltage batteries (18V or 20V) often increase weight, affecting usability during prolonged use.

- A well-chosen battery can reduce downtime from changes, boosting productivity for frequent tasks.

Evaluating Power Output: Watts and Horsepower

When selecting a drill, it’s essential to evaluate its power output, typically measured in watts (W) or horsepower (HP), as these metrics indicate how effectively the tool can perform tasks over time.

For cordless drills, higher power ratings usually mean better performance, especially when tackling demanding tasks. Torque, measured in Newton meters (Nm), complements these power metrics by showing how much rotational force the drill can exert.

More watts generally translate into higher torque, allowing you to drill through tougher materials and drive larger fasteners efficiently.

Always consider both wattage and torque ratings to guarantee the drill meets your project’s requirements. A drill with higher power output will save you time and effort on heavy-duty applications, making it a smart investment.

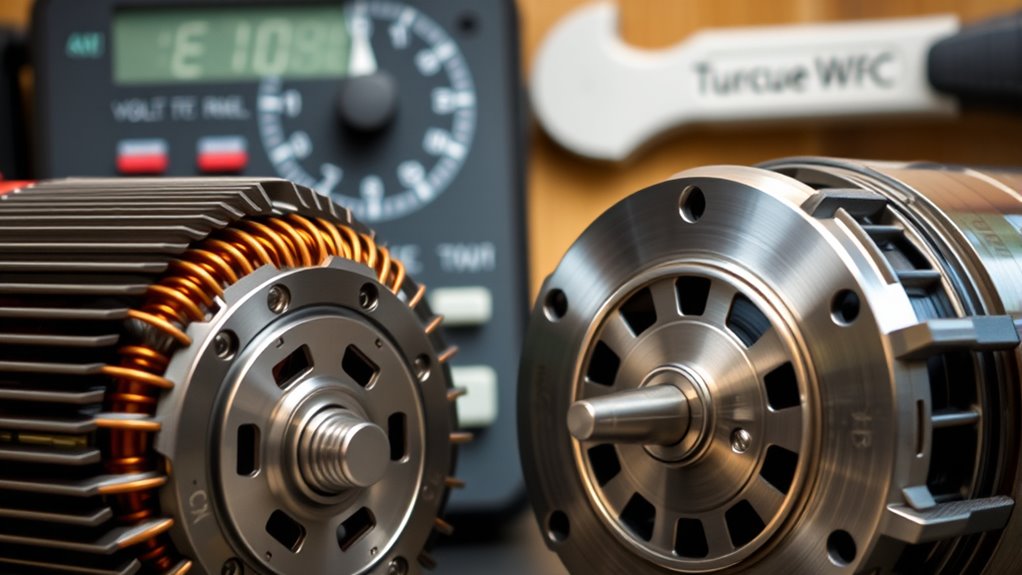

The Impact of Motor Types: Brushed vs. Brushless

When choosing between brushed and brushless motors, efficiency and cost are key factors to evaluate.

Brushless motors offer greater efficiency and longer lifespans, making them ideal for heavy-duty tasks.

While they might’ve a higher upfront cost, the long-term savings and performance benefits often outweigh this initial investment.

Efficiency Differences Explained

Understanding the efficiency differences between brushed and brushless motors is essential for choosing the right drill for your needs.

When it comes to cordless drills, consider these key points:

- Brushed motors use brushes, leading to increased friction and reduced efficiency.

- Brushless motors eliminate brushes, resulting in smoother operation and enhanced efficiency.

- Brushless options offer longer runtimes and more power output, ideal for heavy workloads.

- While brushed motors are cheaper for occasional use, brushless motors are a better long-term investment.

Your choice impacts torque delivery and overall efficiency, ensuring you select a drill that meets your demands.

For rigorous tasks, brushless motors are often the superior choice, providing not only performance but also longevity in your toolbox.

Cost Considerations Explained

While brushed motors may seem budget-friendly at first glance, their ongoing maintenance costs can add up quickly.

If you’re using corded drills occasionally, they might be a cost-effective choice. However, frequent users should consider investing in brushless motors.

Though they come with a higher initial price—typically 10% to 30% more than brushed models—they offer better long-term value.

Brushless motors operate cooler, provide smoother performance, and require less maintenance, which translates to a longer lifespan.

This reduced need for replacements means you’ll save money over time.

Ultimately, if you value efficiency and productivity, opting for brushless motors can be a smart investment that pays off in the long run.

Choosing the Right Drill for Your Projects

How do you choose the right drill for your projects? It’s crucial to match the drill to your specific needs. Here are some key considerations:

- Voltage: Select a drill with 12V for light tasks and 18V or 20V for heavy workloads.

- Torque: Higher torque settings help with larger fasteners and harder materials.

- Type: Decide between corded and cordless drills based on mobility and power requirements.

- Drill Bits: Use the right drill bit for the material you’re working with, adjusting speed and torque accordingly.

Whether you’re putting together furniture or tackling demanding projects, understanding these factors will guarantee you pick the right drill to get the job done efficiently.

Understanding Drill Settings for Optimal Use

What makes the difference between a successful and a frustrating drilling experience? Understanding drill settings is key.

Adjusting torque settings on your drill prevents over-driving screws, especially in soft materials like drywall, which need lower torque. The numbers on the chuck indicate different torque limits—lower for delicate tasks and higher for dense materials.

Speed settings marked on a switch let you tailor your drill’s performance; higher numbers mean faster speeds, perfect for tougher jobs. Always make torque and speed adjustments when the drill is at a complete stop to avoid gear damage.

For long screws, combine slower speeds with medium to high torque settings. This approach yields better results and minimizes the risk of stripping the screw head.

The Role of Chuck Size and Type in Drilling

Selecting the right drill settings is just the start; understanding the role of chuck size and type can greatly enhance your drilling experience. Here are key factors to take into account:

- Chuck size affects the size of drill bits you can use, like 1/4-inch for smaller tasks or 1/2-inch for heavier applications.

- Keyed chucks offer a secure grip but require a tool for adjustments, while keyless chucks allow for quick, tool-free bit changes.

- The chuck type influences versatility, enabling you to use both drill and screwdriver bits.

- Torque range on the chuck, typically from 1 to 20, determines how effectively you can drive screws or drill into various materials.

Choosing the right chuck guarantees compatibility and maximizes efficiency, keeping your projects smooth and damage-free.

Tips for Selecting the Best Drill for Your Needs

When it comes to finding the best drill for your needs, consider the specific tasks you’ll tackle. For basic household projects, a lower voltage drill (9-14 volts) works well, while larger jobs call for higher voltage (18-24 volts) for added power.

Pay attention to the ampere-hour (Ah) rating; higher Ah means longer battery life, essential for extended tasks. If efficiency and longevity are priorities, opt for drills with brushless motors, which require less maintenance.

Evaluate torque settings, too; higher torque lets you handle larger fasteners and tougher materials like hardwood or metal.

Finally, choose a drill that feels comfortable and well-balanced in your hand, as this reduces wrist strain during prolonged use, making your work easier.

Frequently Asked Questions

What Voltage Power Drill Do I Need?

When deciding what voltage power drill you need, think about the tasks you’ll tackle.

If you’re handling light-duty jobs, a 12V drill should work well. For more demanding projects, consider an 18V or 20V model for better power and torque.

If you’re into DIY, a 14.4V drill offers a great balance.

Is a 21V Drill Better Than 18V?

Imagine two knights, one wielding an 18V sword and the other a mighty 21V blade.

If you’re tackling tough quests, the 21V knight’s power can conquer dense materials with ease, thanks to its higher torque.

But for lighter tasks, the 18V knight can still triumph.

Just remember, the heavier 21V can wear you down over long battles, and finding its armor—replacement batteries—might be trickier.

Choose wisely for your journey!

Is a Higher Volt Drill Better?

A higher voltage drill can be better for certain tasks. If you’re tackling tough materials or larger fasteners, those extra volts give you more power and torque, making your job easier.

However, if you’re just doing basic household tasks, a lower voltage drill might suffice.

Keep in mind that factors like motor type and torque ratings also play a role in performance, so it’s important to evaluate your specific needs before choosing.

What Do the Numbers Mean on My Drill?

Did you know that using the right torque setting can improve your drilling efficiency by up to 30%?

The numbers on your drill’s chuck indicate torque levels, ranging from 1 to 20. Lower numbers are for softer materials, while higher ones provide more power for denser surfaces.

If you see a drill bit symbol, it means you can bypass the clutch for maximum torque.

Always match these settings to your material for the best results!

Conclusion

In the world of drilling, understanding voltage and torque is like knowing the foundation of a sturdy house. You need the right tools for the job, ensuring they match your project’s requirements. By considering factors like power type, battery capacity, and drill settings, you can make informed choices that lead to successful results. So, pick your drill wisely, and you’ll build not just projects, but your skills and confidence as well. Happy drilling!