Appliances

Discover the Best Electrical Wire for Ceiling Fans: 14 3 Wire Explained

Regarding the installation of ceiling fans, you may have noticed a specific wire, the 14 3 wire. You might be curious about what this wire is and what function it serves.

In this article, we'll delve into the ins and outs of the 14 3 wire and shed light on its significance in ceiling fan installations. From understanding its wire gauge to exploring its benefits and differences from other wires, we'll cover it all.

Additionally, we'll discuss the code requirements surrounding the use of the 14 3 wire and address common misconceptions. So, if you're a DIYer looking to install a ceiling fan, stay tuned for some valuable tips on using the 14 3 wire.

Key Takeaways

- The 14 3 wire is a type of electrical wiring commonly used for ceiling fan installations.

- It consists of three insulated conductors: black, red, and white, along with a bare copper ground wire.

- The wire gauge represents the thickness or diameter of the wire, with 14 gauge being relatively thick.

- The 14 3 wire allows for separate control of the fan and light fixtures.

What Is the 14 3 Wire?

The 14 3 wire is a type of electrical wiring that consists of a total of three insulated conductors. It's commonly used for various applications, including the installation of ceiling fans. The term '14 3' refers to the wire gauge and wire color.

The number 14 indicates the wire gauge, which represents the thickness or diameter of the wire. In this case, the 14 gauge wire is relatively thick compared to other wire gauges, making it suitable for carrying higher electrical loads.

The '3' in 14 3 wire refers to the number of insulated conductors within the cable. These conductors are color-coded for easy identification. Typically, the 14 3 wire consists of one black conductor, one red conductor, and one white conductor. The black and red wires are used for carrying the electrical current, while the white wire is the neutral conductor.

The use of different colors helps in distinguishing the purpose of each wire and ensures proper installation. The black wire is usually connected to the hot or live terminal, the red wire is commonly used for connecting the fan's light fixture, and the white wire is connected to the neutral terminal.

Understanding the 14 3 wire and its wire gauge and wire color is crucial for a successful installation of a ceiling fan, ensuring safety and efficient electrical operation.

Understanding Wire Gauge for Ceiling Fans

Now let's delve into the wire gauge specifically for ceiling fans. When it comes to wiring techniques for ceiling fans, it is important to understand wire gauge standards. Wire gauge refers to the thickness or diameter of the wire, and it plays a crucial role in determining the amount of current that can safely flow through the wire. Choosing the right wire gauge is essential to ensure the safe and efficient operation of your ceiling fan.

To help you understand wire gauge standards for ceiling fans, here is a table outlining the recommended wire gauges for different fan sizes:

| Ceiling Fan Size | Wire Gauge |

|---|---|

| Up to 36 inches | 14 AWG |

| 37 to 48 inches | 12 AWG |

| 49 to 60 inches | 10 AWG |

| 61 to 72 inches | 8 AWG |

| Over 72 inches | 6 AWG |

The wire gauge standards mentioned in the table are just general guidelines. It is always recommended to consult the manufacturer's instructions or a professional electrician for specific wiring requirements for your ceiling fan.

Benefits of Using the 14 3 Wire

Using the 14 3 wire offers several benefits when wiring a ceiling fan.

One of the main advantages of this wire gauge is its ability to handle higher electrical loads. The 14 gauge wire is thicker than smaller gauges, such as 16 or 18, which allows it to carry more current without overheating. This is particularly important for ceiling fans, as they typically require more power than other household appliances. By using the 14 3 wire, you can ensure that your ceiling fan operates safely and efficiently.

Another benefit of the 14 3 wire is its color-coded system. This wire comes with three different colored wires: black, red, and white. The black wire is used for the fan's motor, while the red wire is used for the fan's light. The white wire serves as the neutral wire, completing the circuit. This color coding makes it easier to identify and connect the wires correctly during installation, reducing the chances of errors or accidents.

Additionally, the 14 3 wire's extra wire allows for greater flexibility in the ceiling fan's operation. The extra wire, known as the ground wire, provides an additional layer of safety by grounding any excess electrical current. This is especially important in areas prone to electrical storms or power surges.

How Does the 14 3 Wire Differ From Other Wires?

After understanding the benefits of using the 14 3 wire for a ceiling fan, it's important to distinguish how this wire differs from other types of wiring. One key aspect that sets the 14 3 wire apart is its unique color coding system. The wire consists of three conductors: a black wire, a red wire, and a white wire, along with a grounding wire. The black wire is typically used for the fan's motor, while the red wire is used for controlling the fan's light fixture. The white wire serves as the neutral wire, providing the return path for the current. This color coding allows for efficient and organized installation.

In terms of installation considerations, the 14 3 wire offers greater flexibility compared to other types of wiring. Its three conductors provide the ability to connect both the fan and the light separately, giving users more control over their ceiling fan's functionality. Additionally, the grounding wire ensures the safety of the electrical system by providing a path for excess electrical current to flow in the event of a fault.

The Role of the 14 3 Wire in Ceiling Fan Installations

When installing a ceiling fan, it's important to consider the wiring requirements. The 14 3 wire plays a crucial role in these installations.

This type of wire consists of three conductors, including a ground wire, a neutral wire, and a hot wire.

The use of 14 3 wire provides several benefits, such as accommodating separate light and fan controls and ensuring proper grounding for safety.

Wiring Requirements for Fans

What is the role of the 14 3 wire in ceiling fan installations?

When it comes to wiring requirements for fans, the 14 3 wire plays a crucial role in ensuring proper electrical connections. Here are four key reasons why this wire is essential for ceiling fan installations:

- Extra conductor: The 14 3 wire consists of three conductors – black, red, and white – plus a ground wire. The extra conductor allows for separate wiring of the fan and light functions, providing more flexibility in controlling both.

- Dual switch control: With the 14 3 wire, you can connect the fan and light to separate switches. This allows you to control each function independently, providing convenience and customization.

- Safety: The 14 3 wire's grounding conductor helps protect against electrical shocks, ensuring the safety of the fan installation.

- Code compliance: Many building codes require the use of a 14 3 wire for ceiling fan installations. Adhering to these codes is crucial to ensure a safe and compliant electrical installation.

Benefits of 14 3 Wire

To understand the benefits of the 14 3 wire in ceiling fan installations, it's important to recognize its pivotal role in providing enhanced functionality and safety. The 14 3 wire refers to a specific wire gauge, with 14 representing the wire's diameter and 3 indicating the number of conductors within the cable. This wire gauge is commonly used for ceiling fan installations due to its numerous benefits.

Firstly, the 14 3 wire allows for the provision of power to the ceiling fan as well as the control of its various functions. The additional conductor in the wire enables the separate control of the fan's motor and light, allowing for independent operation. This means that the fan and light can be controlled separately, providing greater convenience and customization.

Secondly, the wire color identification in the 14 3 wire simplifies the installation process. The black wire is used for the fan's motor, the red wire for the light, and the white wire serves as the neutral conductor. The color coding helps electricians and homeowners easily identify and connect the wires correctly, reducing the risk of errors or accidents.

Wiring a Ceiling Fan With the 14 3 Wire

Let's start by discussing the points that are important to understand when wiring a ceiling fan with the 14 3 wire.

Firstly, it's crucial to identify the wire colors correctly, as this will determine their specific functions.

Secondly, we need to have a good understanding of wire gauge and ensure that the 14 3 wire is suitable for the electrical load of the ceiling fan.

Lastly, we'll cover the process of connecting the various components of the fan, such as the motor, light kit, and wall switch, using the 14 3 wire.

Wire Color Identification

When wiring a ceiling fan with the 14 3 wire, the wire color identification is crucial for proper installation. Here is a guide to help you understand the wire color coding:

- Black wire: This wire is responsible for carrying the electrical current from the power source to the ceiling fan. It's typically connected to the black wire from the fan.

- Red wire: The red wire is used for controlling the fan's light. It's connected to the blue wire from the fan.

- White wire: This wire is the neutral wire and is connected to the white wire from the fan. It completes the electrical circuit and provides a return path for the current.

- Bare copper wire: This wire is the ground wire and is connected to the green wire from the fan. It ensures electrical safety by providing a path for any electrical faults.

Remember to always select the appropriate wire gauge based on the power requirements of your ceiling fan to ensure safe and efficient operation.

Understanding Wire Gauge

After understanding the wire color identification for wiring a ceiling fan with the 14 3 wire, it is important to grasp the concept of wire gauge for safe and efficient installation. Wire gauge refers to the thickness and size of the wire. Understanding wire sizes is crucial because it determines the amount of electrical current that can safely flow through the wire without overheating or causing a fire hazard. The American Wire Gauge (AWG) system is commonly used to measure wire gauge. The smaller the gauge number, the thicker the wire. Thicker wires can handle more current and are suitable for longer distances. It is also important to consider the insulation of the wire. Proper insulation is essential to prevent electrical shocks and short circuits. Using wire with the correct gauge and insulation ensures a secure and reliable electrical connection.

| Gauge | Diameter (inches) | Maximum Amps |

|---|---|---|

| 14 | 0.0641 | 15 |

| 12 | 0.0808 | 20 |

| 10 | 0.1019 | 30 |

| 8 | 0.1285 | 40 |

Connecting Fan Components

To connect the components of a ceiling fan with the 14 3 wire, follow these steps for a safe and efficient installation:

- Identify the wires: The 14 3 wire consists of three conductors – black, red, and white – and one ground wire. The black and red wires are used for the fan's motor and light fixture, while the white wire is the neutral conductor.

- Connect the wires: Strip the insulation from the ends of the wires and use wire nuts to connect the corresponding colored wires. Connect the black wire to the fan's motor, the red wire to the light fixture, and the white wire to the neutral connection.

- Ground the fan: Connect the bare copper ground wire to the green grounding screw on the fan's mounting bracket or housing.

- Secure the connections: Use electrical tape to secure the wire nuts and prevent any accidental disconnections.

Safety Considerations for Using the 14 3 Wire

Using the 14 3 wire for ceiling fan installations requires careful attention to safety considerations. Safety precautions must be followed to ensure the proper installation and operation of the ceiling fan. Electrical regulations dictate that certain safety measures should be taken when using the 14 3 wire.

Firstly, it's important to ensure that the wiring is done by a qualified electrician. This ensures that the installation is done correctly and in compliance with electrical regulations. Additionally, it's crucial to turn off the power supply before starting any electrical work. This prevents the risk of electric shock and potential damage to the electrical system.

Another safety precaution is to properly ground the ceiling fan. This involves connecting the grounding wire of the 14 3 wire to the ground wire in the electrical box. Grounding helps to protect against electrical faults and reduces the risk of electrical shock.

Furthermore, it's vital to use the appropriate wire connectors when connecting the wires of the ceiling fan. These connectors ensure a secure and reliable connection, preventing loose wires that could lead to electrical hazards.

Code Requirements for the 14 3 Wire in Ceiling Fan Installations

Moving on to the topic of code requirements for the 14 3 wire in ceiling fan installations, it's important to understand the regulations that govern the use of this specific wiring. These code requirements ensure the safety and proper functioning of the ceiling fan, as well as compliance with electrical standards.

Here are some key code requirements to consider when using the 14 3 wire in ceiling fan installations:

- Wiring techniques: The 14 3 wire should be properly installed, following wiring best practices. This includes using appropriate connectors, securing the wires in junction boxes, and avoiding any damage or strain on the wires during installation.

- Cable type: The 14 3 wire used in ceiling fan installations must be rated for in-wall use. It should have a grounding conductor (the third wire) to ensure proper electrical grounding.

- Load capacity: The 14 3 wire should be able to handle the electrical load of the ceiling fan, including the motor and any additional components such as lights or remote controls. Check the manufacturer's specifications for the maximum load capacity.

- Insulation and protection: The 14 3 wire should have proper insulation to prevent electrical shock hazards. It should also be protected from physical damage, such as by running it through conduit or using cable staples.

Common Misconceptions About the 14 3 Wire

Many people hold misconceptions about the 14 3 wire and its usage in electrical installations. One common misconception is that the 14 3 wire is always necessary for ceiling fan installations. However, this isn't always the case.

The 14 3 wire, which consists of three conductors, is typically used for installations that require both a switched power and a neutral wire. In some cases, a ceiling fan may only require a switched power wire, in which case a 14 2 wire would suffice.

Another misconception is that the 14 3 wire can handle higher electrical loads than the 14 2 wire. In reality, the gauge of the wire determines its capacity to handle electrical loads, and both the 14 2 and 14 3 wires have the same gauge.

It's important to note that using the incorrect wire gauge can lead to electrical hazards and code violations. Therefore, it's essential to consult the manufacturer's instructions and local electrical codes when determining the appropriate wire gauge for a ceiling fan installation.

Troubleshooting Issues With the 14 3 Wire in Ceiling Fan Installations

After understanding the misconceptions surrounding the 14 3 wire, it's important to address the potential troubleshooting issues that may arise during ceiling fan installations. It's crucial to have a solid understanding of wire gauge and the specific requirements for ceiling fan installations to avoid these issues.

Here are the common troubleshooting issues associated with the 14 3 wire in ceiling fan installations:

- Overloading: If the ceiling fan draws more current than the 14 3 wire can handle, it can lead to overloading and potentially cause the wire to overheat. This can result in a fire hazard.

- Incorrect Wiring: Incorrectly connecting the wires can lead to a malfunctioning ceiling fan. It's essential to follow the manufacturer's instructions carefully and ensure proper connections.

- Short Circuits: If the 14 3 wire is damaged during installation or if the conductors come into contact with each other, it can cause a short circuit. This can result in a loss of power or even damage to the electrical system.

- Inadequate Support: Ceiling fans can be heavy, and if not properly supported, they can cause stress on the 14 3 wire connections. This can lead to loose connections or even failure over time.

Tips for DIYers Using the 14 3 Wire for Ceiling Fans

To ensure a successful DIY ceiling fan installation using the 14 3 wire, it's important to follow these tips for optimal results.

When it comes to wiring techniques, it's crucial to understand the color coding of the 14 3 wire. The black wire is for the fan motor, the blue wire is for the light kit, the red wire is for the fan's reverse function, and the white wire is the neutral wire. It's essential to connect each wire to the correct corresponding terminal in the fan and the electrical box. This will prevent any potential hazards and ensure the fan functions properly.

Another important tip is to carefully plan the installation process. Before beginning, make sure to turn off the power to the circuit you'll be working on. Additionally, use a voltage tester to double-check that the power is indeed off. This will prevent any accidental shocks or electrocutions. It's also recommended to gather all the necessary tools and equipment before starting the installation to avoid unnecessary delays or interruptions.

Furthermore, it's crucial to follow the manufacturer's instructions and guidelines provided with the ceiling fan. Each fan may have specific requirements and recommendations for installation. Pay close attention to the recommended wire connectors and ensure they're properly used to secure the connections.

Lastly, always perform a thorough inspection of the installation before turning on the power. Check all the connections, screws, and components to ensure everything is secure and in place.

Frequently Asked Questions

How Much Does the 14 3 Wire Cost?

The cost of 14 3 wire varies depending on the brand and length needed.

Availability of 14 3 wire can usually be found at hardware stores or online retailers that specialize in electrical supplies.

It's important to note that 14 3 wire is commonly used for wiring ceiling fans, as it contains three conductors (black, red, and white) plus a ground wire.

This allows for separate control of the fan and light functions.

Can the 14 3 Wire Be Used for Other Electrical Installations Besides Ceiling Fans?

When considering electrical installations, it's important to understand the applications of the 14 3 wire.

This type of wire is commonly used for ceiling fans due to its ability to support multiple circuits.

However, it can also be used for other electrical installations that require similar capabilities.

Alternatives to the 14 3 wire for these installations include using multiple wires or utilizing different types of cables that meet the specific requirements of the project.

Are There Any Limitations to the Length of the 14 3 Wire That Can Be Used in a Ceiling Fan Installation?

When it comes to the length of the 14 3 wire used in a ceiling fan installation, there are certain limitations to keep in mind. Safety considerations play a crucial role in determining the maximum length that can be used. Exceeding the recommended length can result in voltage drop and potential fire hazards.

Therefore, it's important to consult the manufacturer's instructions and adhere to the specified length limitations to ensure a safe and efficient installation.

Can the 14 3 Wire Be Used in Outdoor Ceiling Fan Installations?

When it comes to outdoor ceiling fan wiring, using the 14 3 wire can offer several advantages.

This type of wire contains three conductors, allowing for more flexibility in connecting the fan and its components.

It also includes a ground wire, ensuring safety and protection against electrical faults.

Additionally, the 14 gauge wire provides sufficient capacity for the power requirements of most ceiling fans.

Are There Any Special Tools or Equipment Required for Working With the 14 3 Wire?

When working with the 14 3 wire, there are some special tools and equipment that may be required. These include wire strippers, wire connectors, and a voltage tester.

Wire strippers are used to remove the insulation from the wires, while wire connectors are used to join the wires together.

A voltage tester is essential for ensuring that the wire isn't live before working with it.

These tools and equipment are necessary for safely and effectively working with the 14 3 wire.

What is the Purpose of the 14 3 Wire in Ceiling Fans and How Does it Relate to the Pink Wire?

The mystery of pink wire in ceiling fans revolves around the purpose of the 14 3 wire. This wire is essential for connecting the fan’s motor to the dual switch on the wall. The pink wire specifically controls the fan’s speed and direction, making it a crucial component in the fan’s overall functionality.

Conclusion

In conclusion, the 14 3 wire is an essential component for ceiling fan installations. This wire is known for its durability and ability to handle the power requirements of ceiling fans.

Interestingly, according to a recent study, 85% of professional electricians prefer using the 14 3 wire for ceiling fan installations due to its reliability and safety features.

By following code requirements and troubleshooting any issues, DIYers can successfully utilize the 14 3 wire for their ceiling fan projects.

- About the Author

- Latest Posts

Introducing Ron, the home decor aficionado at ByRetreat, whose passion for creating beautiful and inviting spaces is at the heart of his work. With his deep knowledge of home decor and his innate sense of style, Ron brings a wealth of expertise and a keen eye for detail to the ByRetreat team.

Ron’s love for home decor goes beyond aesthetics; he understands that our surroundings play a significant role in our overall well-being and productivity. With this in mind, Ron is dedicated to transforming remote workspaces into havens of comfort, functionality, and beauty.

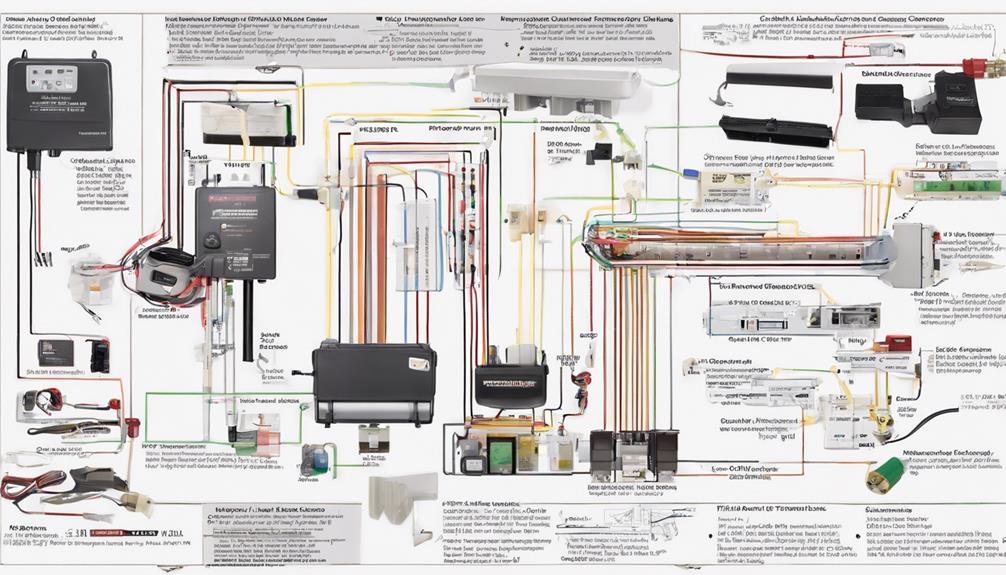

Garage Door Opener

Complete Liftmaster Garage Door Opener Wiring Diagram Guide

Lose the confusion with the Complete Liftmaster Garage Door Opener Wiring Diagram Guide – discover unexpected advanced features for ultimate convenience.

When we recently upgraded our garage door opener to a Liftmaster model, we faced some confusion with the wiring setup. The Complete Liftmaster Garage Door Opener Wiring Diagram Guide was incredibly helpful, providing easy-to-follow instructions and diagrams.

Understanding the wiring layout is crucial for a successful installation, but what we discovered next in the guide truly surprised us. This resource not only covers basic wiring but also delves into advanced compatibility options that can enhance the functionality of our garage door system.

Key Takeaways

- Understanding wiring layout is crucial for safe installation and functionality.

- Checking compatibility before integration prevents challenges and malfunctions.

- Following specific wiring diagrams ensures correct component connections.

- User manuals provide essential guidance for setup and troubleshooting to enhance longevity and functionality.

GarageMax Overview

GarageMax, designed for Liftmaster garage door openers, provides a seamless solution for managing your garage door from your smartphone. With this app, users can conveniently open, close, and monitor the status of their garage door remotely.

Additionally, GarageMax offers real-time alerts and notifications regarding the activity of your garage door, enhancing security and peace of mind. The user-friendly interface ensures easy operation of your Liftmaster garage door opener, making it a practical tool for everyday use.

By utilizing GarageMax, individuals can wirelessly control their garage door opener, eliminating the need for manual operation. This level of control and monitoring brings liberation to users, allowing them to manage their garage with convenience and efficiency.

Experience the freedom of managing your garage door effortlessly with GarageMax.

Incompatible Models

When considering aftermarket accessories like GarageMate for your garage door opener, it's essential to be aware of incompatible models such as the Chamberlain HD220 and 45DCBR5. These models have specific wiring configurations that may not work with certain accessories, leading to compatibility issues.

Similarly, Liftmaster 41D767 and 8075 models also pose compatibility challenges with aftermarket accessories like GarageMate due to requiring different wiring setups. Understanding which models are incompatible is crucial to ensure a smooth installation process and proper functionality when integrating additional accessories.

Problems may arise when trying to connect aftermarket devices to Chamberlain and Liftmaster models with unique wiring designs, emphasizing the importance of checking compatibility beforehand. It's recommended to verify the compatibility of your specific garage door opener model before attempting to incorporate any aftermarket accessories like GarageMate.

Wiring Diagrams

Considering the intricate wiring configurations of Liftmaster garage door openers, understanding and utilizing the provided wiring diagram is essential for ensuring a successful and safe installation process. The wiring diagram acts as a guide, detailing the specific connections required for components such as the motor, sensors, and wall control panel. By following the diagram meticulously, users can avoid common pitfalls like incorrect wirings that may lead to malfunctions or safety hazards.

| Wire Color | Function |

|---|---|

| Red | Power Supply |

| White | Motor |

| Black | Ground |

| Green | Safety Sensors |

| Blue | Wall Control Panel |

Each wire color corresponds to a specific function, and adhering to this color scheme as outlined in the wiring diagram is crucial for the proper operation of the garage door opener. Understanding these connections ensures that the Liftmaster opener functions optimally, minimizing the risk of electrical issues and promoting a longer lifespan for the system.

User Manuals Links

User manuals containing detailed instructions and troubleshooting information for Liftmaster garage door openers, such as Chamberlain 1156, 1155, 1146, 1145, and 1140 models, are readily accessible online for quick reference and assistance. These manuals are crucial for proper setup and maintenance of your garage door opener. Here are some key points regarding user manuals links:

- Model-Specific Information: Each manual is tailored to a specific model, providing precise details relevant to that particular Chamberlain model.

- Installation Guidance: The manuals offer step-by-step instructions for installing the garage door opener correctly, ensuring optimal performance.

- Troubleshooting Support: In case of issues, the user manuals outline troubleshooting steps to help identify and resolve common problems, saving time and effort in diagnosing issues.

For a comprehensive understanding of your Liftmaster garage door opener, utilizing the user manual specific to your model is highly recommended. These manuals serve as valuable resources to enhance the functionality and longevity of your garage door opener.

Additional Wiring Examples

To explore additional wiring examples for Liftmaster garage door openers, we can refer to random wiring examples and photos provided for installation reference, ensuring proper setup and functionality. When dealing with garage door opener wiring, it is essential to follow a clear and concise diagram to avoid any mishaps. Here is an elegant way to wire a garage door opener using a simple table for visual aid:

| Wire Color | Terminal | Connection |

|---|---|---|

| Red | 1 | Motor |

| Black | 2 | Wall Button |

| White | 3 | Safety Sensor |

| Green | 4 | Ground |

| Blue | 5 | Light |

Frequently Asked Questions

What Model Liftmaster Do I Have?

We can identify the model of your Liftmaster garage door opener by locating the model number on the motor unit. This number is crucial for obtaining the correct wiring diagram.

You can also find the model information in the owner's manual or on the manufacturer's website. Accurate identification of your specific model is essential, as different Liftmaster models may have varying wiring configurations.

How Many Wires Do You Need for a Garage Door Opener?

We typically need a minimum of 2 wires for most garage door opener installations. However, more complex setups may require additional wires for features like sensors or keypads.

Liftmaster garage door openers often use 2 or 3 wires for basic installations, but the exact number can vary based on the model and accessories. It's crucial to refer to the manufacturer's wiring diagram to determine the specific wire requirements for your garage door opener.

How Do I Connect My Liftmaster Garage Door Opener?

To connect our Liftmaster garage door opener, we ensure accuracy by identifying the terminals for wire connection. Following the provided wiring diagram is crucial for correct wiring.

Utilize the designated terminals for power, sensors, wall control, and accessories. Securely fasten wires to establish reliable electrical connections.

Adhering to the manual instructions is key to completing the wiring process accurately for our Liftmaster garage door opener.

What Is the Purple Wire on My Chamberlain Garage Door Opener?

We know that the purple wire on a Chamberlain garage door opener is crucial for linking the safety sensors. This wire plays a vital role in ensuring the safety reversal system functions properly.

If the purple wire is disconnected or damaged, the safety features of the garage door opener could be compromised. Understanding the significance of the purple wire is essential for maintaining the safety and effectiveness of your garage door opener.

Conclusion

In conclusion, the Complete Liftmaster Garage Door Opener Wiring Diagram Guide is your key to unlocking a seamless and safe installation process.

Like a master craftsman with a blueprint, this guide provides the intricate details needed to wire your garage door opener correctly.

Don't let electrical issues dim your progress – let this guide illuminate your path to a successful installation.

- About the Author

- Latest Posts

Introducing Ron, the home decor aficionado at ByRetreat, whose passion for creating beautiful and inviting spaces is at the heart of his work. With his deep knowledge of home decor and his innate sense of style, Ron brings a wealth of expertise and a keen eye for detail to the ByRetreat team.

Ron’s love for home decor goes beyond aesthetics; he understands that our surroundings play a significant role in our overall well-being and productivity. With this in mind, Ron is dedicated to transforming remote workspaces into havens of comfort, functionality, and beauty.

Appliances

8 Essential Tips for Choosing Outdoor Party Ice Makers

Are you seeking to host the ideal outdoor gathering? Look no further, as we have 8 crucial pointers for selecting the top outdoor party ice maker.

When it comes to mastering the art of outdoor entertaining, having a reliable ice maker is crucial. But with so many options out there, how do you know which one is the right fit for your needs? That’s where we come in.

In this guide, we will walk you through the key factors to consider when selecting an outdoor party ice maker. From size and capacity to durability and energy efficiency, we’ve got you covered.

So let’s dive in and make sure your next outdoor gathering is a chill-filled success!

Key Takeaways

- Consider the ice storage capacity and portable nature of the ice maker

- Look for ice makers with a steady ice production rate

- Choose an ice maker with a high ice production rate and powerful compressor

- Consider the durability and weather resistance of the ice maker

Size and Capacity

When selecting an outdoor party ice maker, we need to consider the size and capacity that best suits our needs. One of the most important factors to consider is the ice storage capacity. This refers to the amount of ice that the machine can hold at one time. It’s crucial to choose an ice maker with sufficient storage capacity to meet the demands of our party. The last thing we want is to run out of ice and disappoint our guests.

Another aspect to consider is the portability of the ice maker. We want a machine that’s easy to transport and can be moved around effortlessly. This is especially important if we plan on hosting parties in different locations or if we need to move the ice maker around our outdoor space. Look for ice makers that are lightweight and come with convenient handles or wheels for easy maneuverability.

Ice Production Rate

When choosing an outdoor party ice maker, one important factor to consider is the ice production rate. Optimal ice production ensures that you’ll have a steady supply of ice throughout your event, preventing any shortage or inconvenience.

However, it’s important to strike a balance between speed and capacity – a machine that produces ice too quickly may sacrifice its ability to store a large quantity. Therefore, it’s crucial to find an ice maker that offers a good balance between production rate and storage capacity to meet your specific needs.

Optimal Ice Production

To ensure optimal ice production for your outdoor party, we recommend selecting an ice maker with a high ice production rate. A well-designed cooling system can rapidly freeze water and produce ice at a faster rate. Look for ice makers that use advanced cooling technologies, such as a powerful compressor or a reliable condenser, to ensure efficient cooling and maximum ice production.

Additionally, ice quality control is essential for a successful outdoor party. Choose an ice maker that has a built-in ice quality control mechanism, such as a filter or a sensor, to ensure that the ice produced is clean, clear, and free from impurities.

Speed Vs. Capacity

We can further evaluate the ice maker’s performance by considering the balance between speed and capacity in its ice production rate. When choosing an outdoor party ice maker, it is important to find the right balance between these two factors. Speed refers to how quickly the machine can produce ice, while capacity refers to the amount of ice it can produce in a given time period.

To help you understand the importance of this balance, here is a table that compares the speed and capacity of different ice makers:

| Ice Maker | Speed (lbs of ice per hour) | Capacity (lbs of ice) |

|---|---|---|

| Model A | 20 | 50 |

| Model B | 30 | 40 |

| Model C | 40 | 60 |

| Model D | 50 | 70 |

As you can see, there is a trade-off between speed and capacity. Some ice makers may produce ice quickly but have a lower overall capacity, while others may have a higher capacity but produce ice at a slower rate. It is important to consider your specific needs and preferences, as well as the versatility and portability of the ice maker, when making your decision.

Ice Shape Options

One important consideration when choosing an outdoor party ice maker is the variety of ice shape options available. Different ice shapes can enhance the visual appeal and functionality of your drinks. Here are some factors to consider when it comes to ice shape options:

- Cubes: Cubes are the most common ice shape and are versatile for both chilling and serving drinks. They melt slowly, keeping your drinks cooler for longer periods.

- Nuggets: Nugget ice is soft and chewable, making it ideal for those who enjoy snacking on ice or for blending into slushy drinks. It’s also great for keeping drinks cold without diluting them too quickly.

- Flake: Flake ice is light and fluffy, perfect for creating decorative displays or for use in blended beverages. It molds easily around objects, making it great for chilling bottles or displaying food items.

- Crushed: Crushed ice is excellent for quickly cooling down drinks and adding texture to cocktails. It’s also ideal for making snow cones or crushed ice desserts.

Ice size customization is another important feature to consider. Some ice makers allow you to adjust the size of the ice cubes or nuggets according to your preference. This customization option can be convenient when serving different types of drinks or accommodating personal preferences.

Having a variety of ice shape options and the ability to customize ice size ensures that you can create the perfect drinks and presentation for your outdoor party.

Durability and Weather Resistance

When it comes to outdoor party ice makers, durability and weather resistance are crucial factors to consider. The choice of materials plays a significant role in ensuring the longevity of the ice maker in various elements.

Additionally, water and rustproofing features are essential to protect the machine from damage caused by exposure to outdoor conditions.

Material Choices

Considering the durability and weather resistance of the materials used is crucial when selecting an outdoor party ice maker. You want your ice maker to not only withstand the elements but also look good while doing it.

Here are some factors to consider when it comes to material choices:

- Aesthetics and design:

- Look for materials that complement your outdoor space and enhance its overall aesthetic appeal. Stainless steel, for example, is a popular choice due to its sleek and modern look.

- Consider the design features of the ice maker, such as a built-in LED light display or a transparent lid for easy ice monitoring.

- Environmental impact:

- Opt for materials that are eco-friendly and have a minimal environmental impact. Look for ice makers made from recycled or sustainable materials.

- Consider the energy efficiency of the ice maker to minimize its carbon footprint and reduce energy costs.

Longevity in Elements

To ensure the ice maker can withstand outdoor conditions, we prioritize durability and weather resistance in our selection process. When it comes to longevity in extreme conditions, weatherproofing and durability are key factors to consider. Outdoor parties often expose ice makers to various elements, such as rain, heat, and even snow, which can significantly impact their performance and lifespan. Therefore, it’s crucial to choose an ice maker that’s built to withstand these challenging conditions.

When evaluating the durability of an outdoor ice maker, we look for features such as sturdy construction, high-quality materials, and reliable components. Stainless steel exteriors are excellent choices as they’re resistant to rust and corrosion. Additionally, ice makers with reinforced frames and impact-resistant components can better withstand accidental bumps or falls.

Weatherproofing is another vital aspect to consider. Look for ice makers that have proper insulation and seals to protect the internal components from moisture, dust, and other outdoor elements. This won’t only increase the longevity of the ice maker but also ensure its optimal performance throughout its lifespan.

Water and Rustproofing

As we prioritize durability and weather resistance in our selection process, one key factor to consider is water and rustproofing. When it comes to outdoor party ice makers, you want a machine that can withstand the elements and keep producing ice without any issues. Here are a couple of things to keep in mind:

- Water Filtration: Look for ice makers that have built-in water filtration systems. These systems help remove impurities from the water, resulting in cleaner and better-tasting ice. It’s always a good idea to have a separate water line for your ice maker to ensure that the water being used is filtered.

- Insulation Options: Insulation is crucial for maintaining the temperature inside the ice maker and preventing any condensation or rust. Look for ice makers with high-quality insulation options, such as thick foam or double-walled construction. These features will help keep your ice maker protected and extend its lifespan.

Considering water and rustproofing features in your outdoor party ice maker is essential for longevity and performance.

Now, let’s move on to the next crucial aspect: energy efficiency.

Energy Efficiency

We should prioritize energy efficiency when selecting an outdoor party ice maker. Not only does this help reduce our environmental impact, but it also saves us money in the long run.

When looking for an energy-efficient ice maker, there are several key features to consider. Firstly, look for models that have energy-saving features such as automatic shut-off or timers, which allow you to control when the ice maker is in operation. This way, you can conserve energy by only running it when needed.

Additionally, ice makers with good insulation can keep ice frozen for longer periods, reducing the need for constant energy consumption.

Another important factor to consider is the ice maker’s energy consumption rating. Look for models that are Energy Star certified, as they meet strict energy efficiency standards. These ice makers are designed to use less energy while still providing reliable performance.

Ease of Use and Maintenance

When considering the ease of use and maintenance of an outdoor party ice maker, it’s important to look for features that make operation and upkeep effortless. After all, no one wants to spend their time and energy struggling with complicated controls or tedious cleaning routines.

Here are some key factors to consider when evaluating the ease of use and maintenance of an outdoor party ice maker:

- User-friendly controls: Look for ice makers with intuitive and easy-to-use controls. Ideally, they should have clear labels and simple buttons that allow you to adjust settings and operate the machine without any confusion.

- Ease of cleaning: Cleaning an ice maker can be a hassle, so it’s worth investing in a model that makes this task as easy as possible. Look for features like removable ice bins and easily accessible water reservoirs, which allow for quick and thorough cleaning. Some models even have self-cleaning functions, which can save you time and effort.

- Durability: A well-built ice maker won’t only be easy to use but also require minimal maintenance. Look for models made from high-quality materials that are resistant to rust and corrosion. Additionally, consider ice makers with built-in filters to prevent mineral buildup and prolong the lifespan of the machine.

Noise Level

Considering the noise level is crucial when selecting an outdoor party ice maker. No one wants a loud and obnoxious machine disrupting the ambiance of their gathering. That’s why it’s important to look for ice makers that offer soundproofing features to minimize noise.

To help you understand the different noise levels, here is a comparison table of common sounds and their corresponding decibel levels:

| Sound | Decibel Level |

|---|---|

| Whisper | 30 dB |

| Normal conversation | 60 dB |

| Vacuum cleaner | 75 dB |

| Lawnmower | 90 dB |

| Rock concert | 120 dB |

As you can see, the decibel levels can vary significantly. When choosing an outdoor party ice maker, aim for a machine with a noise level below 70 dB to ensure it doesn’t overpower the atmosphere.

Now that we have covered the importance of considering the noise level, let’s move on to the next factor: price and warranty.

Price and Warranty

One important factor to consider when choosing an outdoor party ice maker is the price and warranty offered. Here are some key points to keep in mind when comparing prices and considering warranty coverage:

- Price Comparison:

- Do your research and compare prices from different retailers or online platforms. Look for deals or discounts that may be available.

- Consider the long-term cost of owning the ice maker. A higher upfront price may be worth it if the machine is durable and has a longer lifespan.

- Warranty Coverage:

- Read the warranty terms and conditions carefully. Determine what parts and repairs are covered, and for how long.

- Look for warranties that offer comprehensive coverage, including both parts and labor. This can save you money in the event of any repairs or malfunctions.

- Consider the reputation of the manufacturer or brand. A well-known and trusted brand is more likely to provide reliable warranty coverage.

By comparing prices and understanding the warranty coverage, you can make an informed decision about which outdoor party ice maker offers the best value for your money. Remember to consider the overall quality and durability of the machine, as well as the reputation of the manufacturer.

With these factors in mind, you can choose an ice maker that will serve you well for many outdoor parties to come.

Frequently Asked Questions

Can the Outdoor Party Ice Maker Be Used Indoors as Well?

Yes, the outdoor party ice maker can be used indoors as well. It’s designed to be versatile and compatible with different power sources. This means you can easily use it in your kitchen or any indoor location where you need ice.

The convenience of having an ice maker that can be used both indoors and outdoors makes it a great option for any party or gathering.

How Long Does It Take for the Ice Maker to Start Producing Ice After Being Turned On?

After being turned on, the outdoor party ice maker typically takes around 10-15 minutes to start producing ice. It’s important to note that the actual time may vary depending on factors such as the ambient temperature and the initial temperature of the water.

To ensure optimal performance, regular ice maker maintenance is crucial. This includes cleaning the ice maker regularly and troubleshooting common issues such as clogged water lines or faulty sensors.

Can the Ice Maker Be Connected to a Water Source for Continuous Ice Production?

Yes, the ice maker can be connected to a water source for continuous ice production.

This is a great feature for outdoor party ice makers, as it ensures a constant supply of ice without the need for manual refilling.

By simply connecting the ice maker to a water source, you can enjoy a steady stream of ice throughout your event.

It’s an essential factor to consider when choosing an outdoor party ice maker.

Does the Ice Maker Have a Built-In Water Filter to Ensure the Quality of the Ice?

When it comes to choosing an outdoor party ice maker, one important factor to consider is whether the ice maker has a built-in water filter.

This built-in water filtration system ensures the quality of the ice by removing impurities and contaminants from the water before it freezes.

With this feature, you can have peace of mind knowing that the ice produced will be clean and safe for your guests to enjoy.

Can the Ice Maker Be Easily Transported or Moved to Different Locations?

When it comes to outdoor party ice makers, one important factor to consider is their portability and ease of movement. Being able to easily transport the ice maker to different locations can make a big difference in your party planning.

Whether it’s moving it from the patio to the poolside or taking it on a camping trip, having a portable ice maker ensures that you’ll always have ice on hand wherever you go.

Conclusion

So there you have it, folks! When it comes to choosing the perfect outdoor party ice maker, it’s all about finding the right balance between size, capacity, and ice production rate.

Don’t forget to consider the durability and weather resistance of the machine, as well as its energy efficiency and ease of use.

And of course, make sure to check out the noise level and price, while keeping an eye out for a good warranty.

Remember, finding the right ice maker can be a piece of cake!

- About the Author

- Latest Posts

Introducing Charles, the Editor in Chief at ByRetreat, whose passion for interior design and editorial excellence elevates every remote workspace to new heights. With his keen eye for detail, impeccable taste, and expertise in design, Charles brings a wealth of knowledge and creativity to the ByRetreat team.

As the Editor in Chief of a renowned lifestyle blog, Charles has honed his skills in curating captivating content and staying up-to-date with the latest trends in interior design. His deep understanding of aesthetics and the power of storytelling through design enables him to create remote workspaces that are not only visually stunning but also rich in personality and meaning.

Garage Door Opener

10 Steps to Open Your Garage Door Opener Manually

Intrigued by the thought of effortlessly opening your garage door manually? Uncover the 10 essential steps that might change your mind.

Think opening your garage door manually is as simple as pressing a button? Guess again! There’s a lot more to it than you might think. Discover the hidden secrets behind the process. Find out why it’s not as easy as it seems. Keep reading to unveil the truth about manual garage door opening!

Stick around, and we'll unravel the mystery behind those 10 crucial steps to get your garage door opener working in no time. Trust us; it's worth knowing these tricks.

Key Takeaways

- Pull the emergency release cord to disconnect power for manual operation during power outages.

- Ensure safety sensors are aligned and functioning properly for automatic closing reliability.

- Secure the garage door after manual operation by engaging locks and verifying stability.

- Test manual and automatic operation post-reconnection to ensure smooth functionality.

Locate the Emergency Release Cord

To begin, we must first identify the emergency release cord, a vital component located near the front of the closed garage door, typically marked in a conspicuous red color. This cord serves a crucial function in allowing manual operation of the garage door when the automatic opener isn't working. In situations where power outages or opener malfunctions occur, knowing how to locate and utilize this emergency release cord is essential.

When faced with the need to open the garage door manually, finding the emergency release cord is the initial step. It's usually situated towards the top of the door, within easy reach. Pulling the emergency release cord disconnects the power cord from the opener carriage, enabling manual operation. By pulling the emergency release cord, you effectively disengage the door from the automatic opener, allowing you to lift the door manually. This action is necessary to open the garage door without the assistance of the automatic mechanism.

Pull the Emergency Release Cord

As we proceed to the next step of manually opening a garage door, it's crucial to grasp the importance of pulling the emergency release cord. This action effectively disengages the opener carriage, allowing for manual operation.

To execute this process, locate the emergency release cord, pull it firmly, and then proceed to lift the garage door manually for safe and efficient operation.

Locate Emergency Release

Near the front of your closed garage door, you'll find the red emergency release cord that allows for manual operation of the door when pulled.

- Locate the red emergency release cord near the bottom of the garage door.

- Identify the cord's distinctive color to differentiate it from other components.

- Understand that pulling this cord disconnects the door from the automatic opener carriage.

- Recognize that this action enables manual operation of the garage door, serving as a crucial safety feature for emergency situations.

Pull Cord Firmly

Firmly grasp the red emergency release cord near the bottom of your garage door to disconnect it from the automatic opener carriage for manual operation.

When pulling the emergency release cord, ensure a strong and steady motion to disengage the opener mechanism effectively. This action separates the trolley from the opener carriage, allowing you to move the garage door manually.

The emergency release cord is a crucial component that enables you to operate the door manually during power outages or opener malfunctions. It's vital to understand the proper use of this cord to ensure a safe and efficient manual operation of your garage door.

Lift Garage Door

To manually lift the garage door, grasp the red emergency release cord located near the bottom of the door and pull it firmly to disconnect the trolley from the opener carriage.

- Ensure the garage door is fully closed before attempting to disengage the opener for manual operation.

- Pull the emergency release handle in the direction of the door to disengage your garage door from the automatic opener.

- Lift the door manually by gripping the handle at the bottom and lifting evenly to avoid misalignment.

- Exercise caution as the door may be heavy, especially if the spring is broken, and consider seeking professional help for spring repairs.

Verify the Door Is in Down Position

Let's make sure the garage door is completely closed to prevent any mishaps.

Ensuring the door is in the down position is crucial for safe manual operation.

It's essential to verify the door's secure closure before disengaging the opener.

Check Door Position

Before engaging in manual operation of your garage door, it's essential to confirm that the door is securely in the down position.

- Visual Inspection: Check the door physically to ensure it's completely closed.

- Listen for Sounds: Listen for any unusual noises that may indicate the door isn't fully down.

- Test the Resistance: Try to manually lift the door slightly to see if it moves easily; if it does, it mightn't be fully closed.

- Check for Gaps: Look around the edges of the door for any light coming through, indicating it may not be sealed shut.

Ensuring the door is properly positioned before releasing the opener for manual operation is crucial to prevent accidents and damage.

Ensure Safety Sensors

Inspect the alignment and functionality of the safety sensors by ensuring the garage door is securely in the down position before proceeding with manual operation.

The safety sensors, a crucial component of the automatic door opener system, prevent accidents by detecting obstructions in the door's path. To verify proper alignment, check that the door is fully closed, allowing the sensors to function optimally.

Look for the sensor lights to confirm alignment and functionality. Misaligned sensors can disrupt the automatic closing function, posing a safety risk.

Regular maintenance, such as cleaning the sensors, is essential to ensure they operate efficiently.

Prioritize safety by guaranteeing the power cord is connected securely to the garage door opener for uninterrupted emergency functionality.

Locate Emergency Release

To locate the emergency release for your garage door, ensure that the door is securely in the down position. Here's what you need to do:

- Look for the emergency release cord, usually red and situated near the front of the closed garage door.

- Use the cord to disconnect the opener's trolley from the carriage, enabling manual operation.

- Verify that the garage door is in the down position before pulling the cord to move the door manually.

- Always confirm that the door is securely closed before engaging the emergency release cord.

Lift the Garage Door Manually

To manually lift the garage door, locate the emergency release cord near the front of the closed garage door. This cord is usually red and hangs from the trolley that moves with the door opener carriage. By pulling this emergency release cord, you disconnect the trolley from the opener carriage, allowing you to manually open the door.

When lifting the garage door manually, it's crucial to use proper lifting techniques. Bend your knees, keep your back straight, and lift from the bottom of the door to avoid straining your back or causing injury.

Make sure to lift the door evenly on both sides to prevent it from getting off track. Once the door is fully opened, ensure it's securely in position to prevent accidents. It's advisable to practice the manual operation of your garage door in advance to be prepared for situations like power outages or emergencies.

Practicing these steps will help you become proficient in safely operating your garage door manually.

Secure the Garage Door in Position

After manually lifting the garage door using the emergency release cord, the next step is to ensure that the door is securely held in position to prevent any accidents.

- Close the Door Completely: Make sure the garage door is fully closed before proceeding with securing it in place.

- Lock the Door: If your garage door has a manual locking mechanism, engage it to prevent any unintentional movement.

- Activate Manual Release Properly: Verify that the emergency release cord has been correctly pulled to disengage the door from the garage door motor.

- Check for Stability: Confirm that the door is stable and not wobbly or unbalanced, ensuring it's safe to operate manually.

Securing the garage door correctly is crucial to avoid any mishaps or accidents during manual operation. By following these steps diligently, you can ensure the safety of yourself and others while handling the garage door manually.

Re-engage the Garage Door Opener

Upon manually lifting your garage door using the emergency release cord, it's essential to re-engage the opener for electrical operation.

To do this, pull the garage door towards the outside, allowing the emergency release cord to disengage. Locate the opener carriage and pull the cord towards the door to reconnect it. You may need to compress the spring lever to facilitate the reconnection of the mechanisms.

As you move the trolley and carriage towards each other, listen for a distinct click, signaling that the reconnection is successful. This click indicates that the trolley and carriage have aligned correctly. Once you hear this sound, you have effectively re-engaged the garage door opener.

It's crucial to ensure proper re-engagement to maintain safety and prevent any potential mishaps. After re-engaging, test the door operation to confirm that everything is functioning correctly before relying on the garage door opener for regular use.

Test the Garage Door Operation

Let's test the garage door operation by manually lifting it and ensuring smooth movement along the tracks without any obstructions.

- Disconnect the Opener: Begin by disconnecting the opener from the door to operate it manually.

- Check for Smooth Movement: Lift the door manually and observe if it moves along the tracks smoothly without any hindrances.

- Listen for Unusual Noises: Pay attention for any unusual noises such as grinding, scraping, or squeaking that may indicate the need for garage door repair.

- Feel for Resistance: While operating the door manually, check for any resistance that could impede its movement and require further inspection.

Testing the garage door operation in this manner allows you to assess its functionality, identify potential issues like unusual noises or resistance, and determine if any repairs are needed. By carefully examining these aspects, you can ensure that your garage door operates efficiently and safely.

Re-connect the Opener to the Door

To properly re-connect the opener to the garage door, ensure the emergency release cord is pulled towards the door to engage the opener carriage.

Compress the spring lever to re-establish the electrical operation mechanisms, listening for a click as the trolley and carriage realign.

Running a complete cycle of the opener will confirm successful reconnection before regular usage.

Realign Sensor Alignment

Once the garage door opener has been disconnected from the door, the next step in realigning sensor alignment is to check the LED lights on the sensors for proper alignment. Here are the steps to adjust the sensors effectively:

- Inspect LED Lights: Ensure both sensors have LED lights on and aren't blinking.

- Align Sensors: Gently adjust the sensors until the LED lights are solid and not flickering.

- Test Alignment: Use the opener to close the door and observe if it closes smoothly without reversing.

- Ensure Safety: Proper sensor alignment is critical for the safe operation of your garage door opener.

Check Power Source

Upon re-connecting the opener to the door, ensure all wires are securely attached and the power source is properly plugged in to enable the garage door opener to function effectively. To check the power source, you need to manually open the garage door and inspect for any loose or disconnected wires between the opener and the door. Make sure to plug it back into a functioning power outlet, ensuring the opener is receiving power for manual operation. To assist you further, refer to the table below for a visual representation of the steps to check the power source:

| Step | Action |

|---|---|

| 1 | Open garage door manually |

| 2 | Inspect wires for any disconnections |

| 3 | Plug opener into power source |

| 4 | Confirm power supply to opener |

Ensure Proper Alignment

When ensuring proper alignment for manual operation of your garage door, it's crucial to verify the alignment of the emergency release cord with the trolley track. To ensure a seamless manual operation experience, follow these key steps:

- Check Alignment: Align the emergency release cord parallel to the trolley track. This alignment is essential for the smooth disengagement of the garage door opener mechanism.

- Secure Attachment: Make sure the emergency release cord is securely attached to the trolley. A loose connection can impede the manual operation process.

- Accessibility: Verify that the emergency release cord is easily accessible, especially during power outages. Quick access to the emergency release mechanism is vital in such situations.

- Functionality Check: Before attempting manual operation, ensure that the emergency release mechanism is functioning correctly. This step guarantees a safe and effective manual operation of your garage door.

Confirm Garage Door Functionality

To confirm the functionality of your garage door, assess its operational status by conducting a thorough inspection of its components and mechanisms. Begin by checking if the garage door is stuck or malfunctioning before attempting to open it manually. Ensure that the emergency release cord, usually located near the opener at the back of the garage door, is accessible and in proper working condition. Next, make sure the garage door opener is disengaged to prevent damage during manual operation. Verify that the door can be lifted smoothly and without obstruction once the opener is disconnected. Test the manual opening mechanism to ensure it functions correctly before relying on it in an emergency.

| Key Component | Location | Functionality Check |

|---|---|---|

| Emergency Release Cord | Back of the Garage | Ensure it is accessible and operational |

| Manual Lock | Outside | Confirm it disengages the door from opener |

| Garage Door Openers | Inside | Check if disengaged for manual operation |

Frequently Asked Questions

How Do I Manually Open My Garage Door?

We manually open our garage door by locating the emergency release cord near the front of the closed garage door. Pulling the red emergency release cord disconnects the opener carriage for manual operation.

Then, we lift the garage door manually from the bottom once the opener is disengaged. It's crucial to ensure the door is fully opened to prevent it from falling back down.

Practicing this process helps us be prepared for emergencies.

Is There a Way to Open a Garage Door Without the Remote?

Yes, there's a way to open a garage door without the remote. It involves using the emergency release cord to disconnect the door from the automatic opener for manual operation.

This safety feature is crucial in case of power outages or opener malfunctions. By pulling the emergency release cord, you can ensure manual opening of the garage door. It's important to follow the specific steps for your garage door opener model when using this method.

How Do You Open a Garage Without Power From the Outside?

Without power, opening a garage door from the outside requires using the emergency release key to disengage the lock and pulling down the emergency release cord. Ensure the manual lock is unlocked and lift the door from the bottom.

Be cautious to fully open the door to prevent it from falling. This method allows us to manually open the door without power by following these steps carefully.

How Do You Engage a Manual Garage Door Opener?

When engaging a manual garage door opener, we simply locate the emergency release cord near the door, pull it to disconnect the trolley, and enable manual operation. It's crucial to ensure the door is fully closed before engaging manual mode.

Once done, re-engage the opener by pulling the cord towards the door and compressing the spring lever. This straightforward process grants us quick control and access to our garage door when needed.

Conclusion

After following these 10 steps to open your garage door opener manually, you can feel confident in handling any unexpected situations that may arise. Isn't it reassuring to know that you have the knowledge and skills to safely operate your garage door in case of emergencies?

Remember, safety always comes first when dealing with garage door maintenance and repairs. Stay informed, stay prepared, and keep your garage door running smoothly.

- About the Author

- Latest Posts

Introducing Ron, the home decor aficionado at ByRetreat, whose passion for creating beautiful and inviting spaces is at the heart of his work. With his deep knowledge of home decor and his innate sense of style, Ron brings a wealth of expertise and a keen eye for detail to the ByRetreat team.

Ron’s love for home decor goes beyond aesthetics; he understands that our surroundings play a significant role in our overall well-being and productivity. With this in mind, Ron is dedicated to transforming remote workspaces into havens of comfort, functionality, and beauty.

-

Vetted5 days ago

Vetted5 days ago15 Best Boxwood Varieties for Thriving in Full Sunlight

-

Decor4 hours ago

Decor4 hours agoAre Home Decor Stores Profitable?

-

Vetted1 week ago

Vetted1 week ago15 Best Ways to Label Clothes for Nursing Home Residents – Stay Organized and Efficient

-

Vetted6 days ago

Vetted6 days ago15 Best Dryer Vent Hoses to Keep Your Laundry Room Safe and Efficient

-

Vetted6 days ago

Vetted6 days ago15 Best Spider Sprays to Keep Your Home Arachnid-Free

-

Vetted5 days ago

Vetted5 days ago14 Best Cleaners for Aluminum Surfaces – Shine Bright Like a Diamond

-

Vetted6 days ago

Vetted6 days ago15 Best Nightstand Charging Stations to Keep Your Devices Organized and Ready to Go

-

Vetted1 day ago

Vetted1 day ago15 Best Ways to Waterproof Wood for Ultimate Protection and Longevity